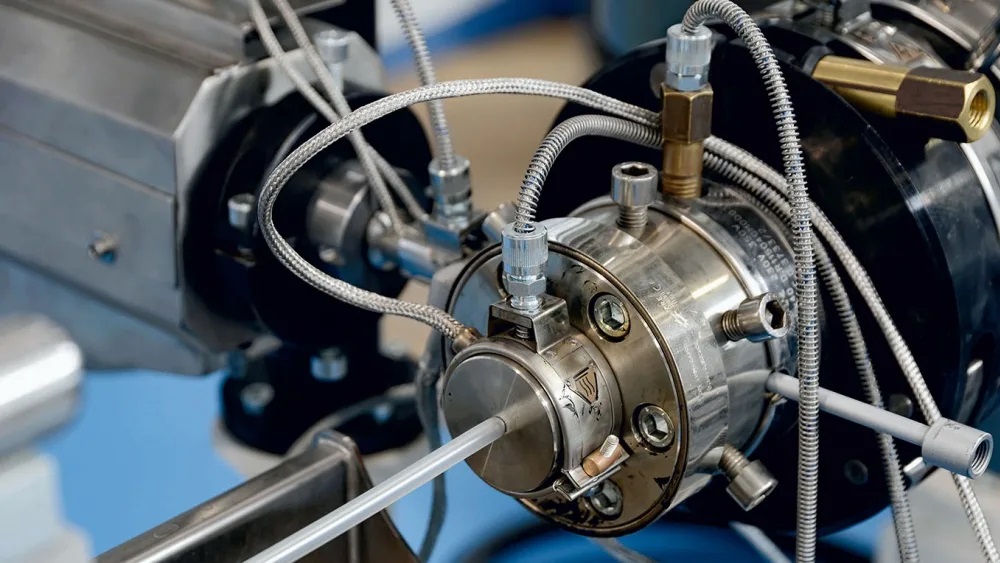

Bausano’s new high-speed line is capable, even in the most compact configuration, of producing up to 120 m of tube per minute. The solution is based on a twin-screw extruder from the Nextmover MD 75/24 series, on which a specially designed stainless-steel head is installed.

The cooling and calibration benches are designed with an idler system to reduce the overall dimensions of the line. In particular, ad-hoc idler systems allow for a threefold increase in the time the tube remains under water, thus ensuring greater efficiency and extrusion speed, with an unrivalled final tube quality.

In this respect, compliance with tolerances, which are particularly tight in the medical sector, is guaranteed by a sophisticated detection system that accurately measures the following parameters: diameter, ovality and wall thickness by laser and ultrasound, cross-section, shape and capacity of the tube, making it possible to rapidly reject non-compliant extrusions.

Another feature is the haul-off unit, which is equipped with a control panel that, when fitted with the detection system, displays speed, measurement data and tolerances on the tube and its alarm systems. Furthermore, brushless motors, on request, help ensure even greater pulling accuracy for complete control of tube tension. Two types of accessories complete the line: the quick cutting system or the automatic winders, whose speed is precisely controlled throughout the winding process.

The company customises each plant based on the customer’s needs, also with regard to the occupied ground volume, through innovative solutions aimed at reducing the size with the same production capacity.

The new high-speed extrusion line for PVC medical tubes meets the most stringent requirements, such as ISO 14644–1 Class 8 Cleanroom, thanks to the strict design criteria adopted, which also ensure high performance in terms of quantity and energy.