Lossburg, 11/10/2022

At K 2022, three Allrounders specially designed for the packaging sector will be on show. As an alternative to thermoforming, an electric Allrounder 720 A with a new injection unit 1300 will be producing thin-walled IML cups at Arburg stand 13A13. Two other innovative applications will be showcased at stands run by partners.

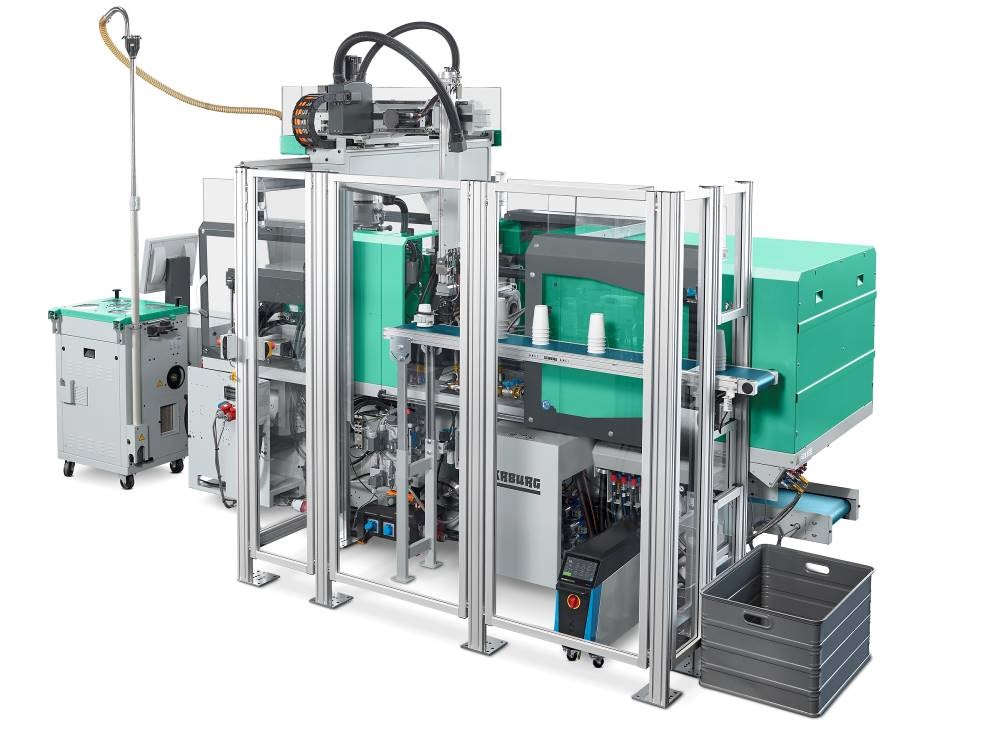

Arburg will be using an electric Allrounder 720 A with a clamping force of 2,900 kN, a new size 1300 injection unit and in the new “Ultimate” performance variant for high-speed and sophisticated processes to demonstrate that high-quality injection moulding technology can be an alternative to thermoforming. The exhibit at K 2022 uses a 4-cavity mould from Brink to produce thin-walled IML round cups from PP monomer material by means of injection compression moulding. The plastic is biomass-balanced and ISCC-certified. Four moulded parts, each weighing 12 grams and with a wall thickness of only 0.37 millimetres, are produced in a cycle time of 3.95 seconds. Also integrated into the production cell is a side-entry robot from Brink that inserts the labels, removes the finished cups and stacks them on a conveyor belt. In this application, special attention was paid to designing parts with low material requirements and to energy efficiency.

Outstanding innovation: foamed cups

Trexel (stand B46, Hall 13) will be exhibiting an outstanding innovation in packaging at K 2022: cost-effective, 430 millilitres holding thermal cups will be produced on an electric Allrounder 520 A with MuCell package in a cycle time of about 5.5. seconds. The cups are not only very light and have excellent insulation properties, but can also be easily recycled after multiple uses. The foamed wall thickness is two millimetres. The MuCell and chemical foaming processes are combined for stable, fast and cost-effective series production. The cups can be used very often and are even lighter than the common disposable alternatives made of paper – while using significantly less material. The product can also be created with any design using the IML process. This pioneering application was developed in a cooperative project between Arburg, Bockatech and other partners Borealis (material), Trexel (MuCell), Roboplas (IML automation) and MCC Verstraete (IML labels).

Refining and separating cups by type

Plasmatreat (stand I65, Hall 11) will be using a “smart” turnkey system based around an IT-networked Allrounder 370 A to demonstrate how production efficiency can be increased with the aid of digitalisation and automation. Printed cups that can be refined inline and separated by type using a digital product passport are produced as part of the R-Cycle initiative. A Multilift V 20 linear robotic system removes the cup and conveys it to plasma treatment, followed by printing in a digital printing station. To allow the cups to be separated by type in a recycling plant after the use phase, each plastic product is given a digital product passport. The pivotal element of R-Cycle is a database that contains all the information about the materials used.

About Arburg

German family-owned company Arburg is one of the world’s leading manufacturers of plastic processing machines. Its product portfolio encompasses Allrounder injection moulding machines with clamping forces of between 125 and 6,500 kN, the Freeformer for industrial additive manufacturing and robotic systems, customer and industry-specific turnkey solutions and further peripheral equipment.

Arburg is a pioneer in the plastics industry when it comes to production efficiency, digitalisation and sustainability. The “arburgXworld” program comprises all digital products and services and is also the name of the customer portal. The company’s strategies regarding the efficient use of resources and circular economy, as well as all related aspects and activities, are outlined in the “arburgGREENworld” program.

Arburg’s central aim is for customers to be able to produce their plastic products, from one-off parts to large-volume batches, in optimum quality at minimum unit costs. The target groups include, for example, the automotive and packaging industries, communication and entertainment electronics, medical technology and the white goods sector.

An international sales and service network ensures first-class customer support at a local level: Arburg has its own organisations at 34 locations in 25 different countries and, together with its trading partners, is represented in more than 100 countries. Its machines are produced exclusively at the company’s German headquarters in Lossburg. Of a total of roughly 3,500 employees, around 2,900 work in Germany. About 600 further employees work in Arburg’s organisations around the world. Arburg has triple certification, in accordance with ISO 9001 (quality), ISO 14001 (environment) and ISO 50001 (energy).

Further information about Arburg can be found at www.arburg.com