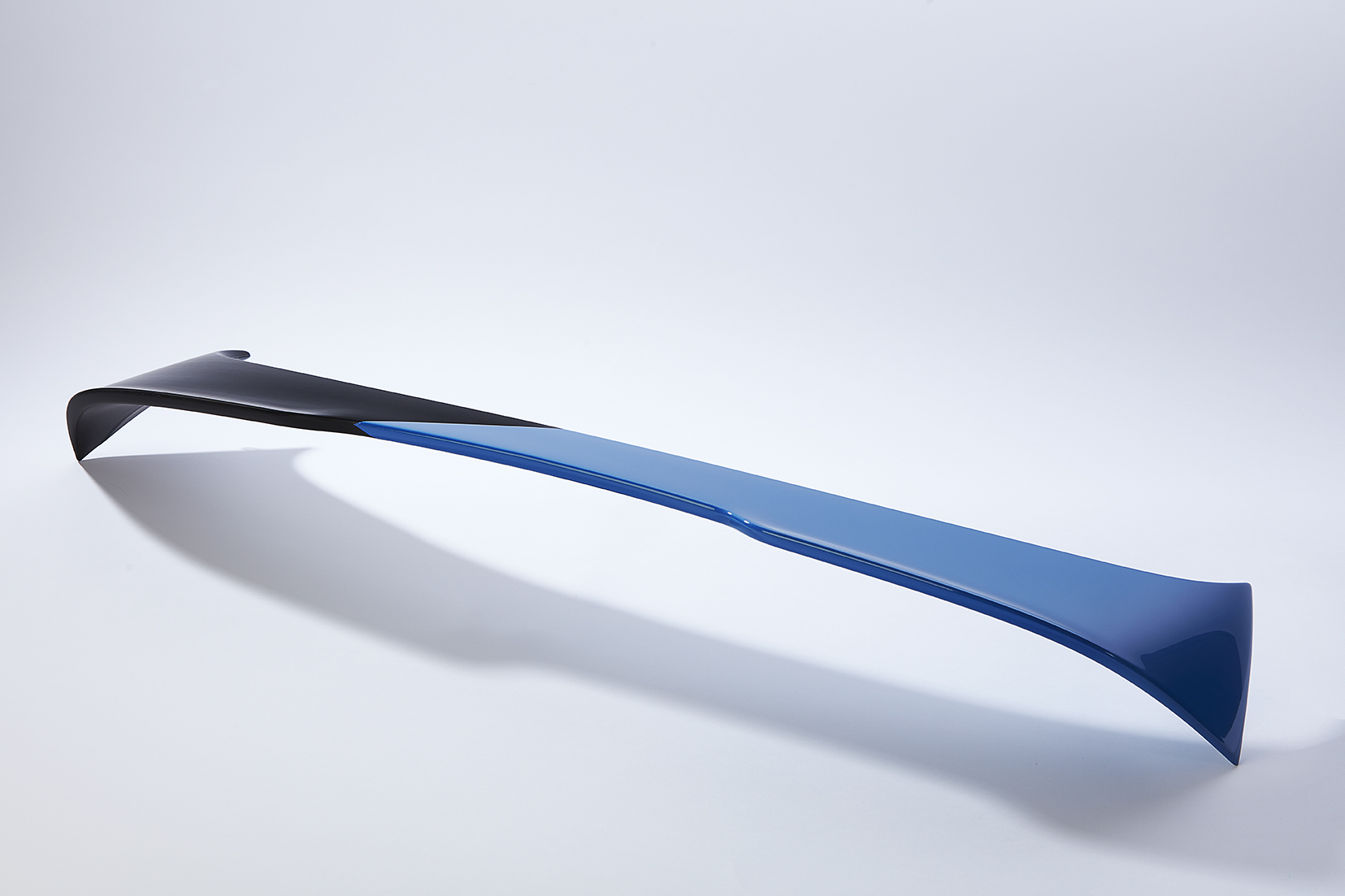

- Novodur® HH-112 delivers best material properties to be selected for roof spoiler application

- Energy and cost savings: Very good paintability without pre-treatment like surface activation

INEOS Styrolution, the global leader in styrenics, announces today that its Novodur HH-112 has been selected by a major European car manufacturer for the blow moulded roof spoiler. Novodur HH-112 is an ABS material specifically designed for highest heat resistance and excellent stiffness.

INEOS Styrolution’s Novodur HH-112 has been selected as the material for the roof spoiler for several reasons including

- Heat performance

- Very good paintability

- Vicat softening temperature of 112 °C

- Melt rheology required for blow moulding processing.

Energy and cost savings are achieved taking advantage of the selected material solution. The material offers the advantage of painting without pre-treatment like surface activation (“flaming”). In addition, the final application is manufactured in a single part vs. multiple parts that have to be assembled.

Car spoilers, in particular roof spoilers, are a trend in the automotive industry that can be observed for several years. As of today, such spoilers are built for about 50 percent of all new cars. Since its colour is customised to the request of the driver, the spoiler may be seen as a signature statement of the car’s owner.

“Due to our long lasting relationship with the customer and the tier 1 supplying this part, an efficient technical cooperation drove to this interesting cost effective solution. With this Novodur HH112 using blow moulding technology, a high quality painted surface was achieved,” summarizes Eric Chambost, Key Account Manager at INEOS Styrolution.