DMG MORI will be presenting the Robo2Go as a mobile automation system for lathes with intuitive programming via CELOS® Powertool.

The core of the integrated turning cell is the new loading and unloading system Robo2Go. Designed for mobile use with up to four lathes, Robo2Go is controlled via CELOS® with just a few entries and without any special knowledge of robots.

The Robo2Go system excels through its flexibility. It can be positioned at different lathes as required with a lifting device in the shortest possible time, which of course maximizes investment security. Free access to the work area of the machine tool remains guaranteed at all times. What makes it so special is that the robot is programmed directly in the machine control with the aid of a special CELOS® powertool. In other words: all the operator has to do is enter the dimensions of the workpiece, the chuck and the gripper, then select one of the pre-defined arrangements of the workpiece tray and finally start the automatic process. „This intuitive way of programming a robot enables especially small and medium-sized enterprises entry into flexible automation without the need of any expert knowledge”, explains Silvio Krüger, CEO of DMG MORI Systems.

This all adds up to make Robo2Go an affordable entry into automated processes with barrier-free safety technology. Use of an area scanner means that Robo2Go can do without protective fences, because the system shuts down as soon as a worker enters the defined safety area. A faster working speed is possible for the robot because this is not a collaborative solution in which the human operator works in the action area at the same time as the robot.

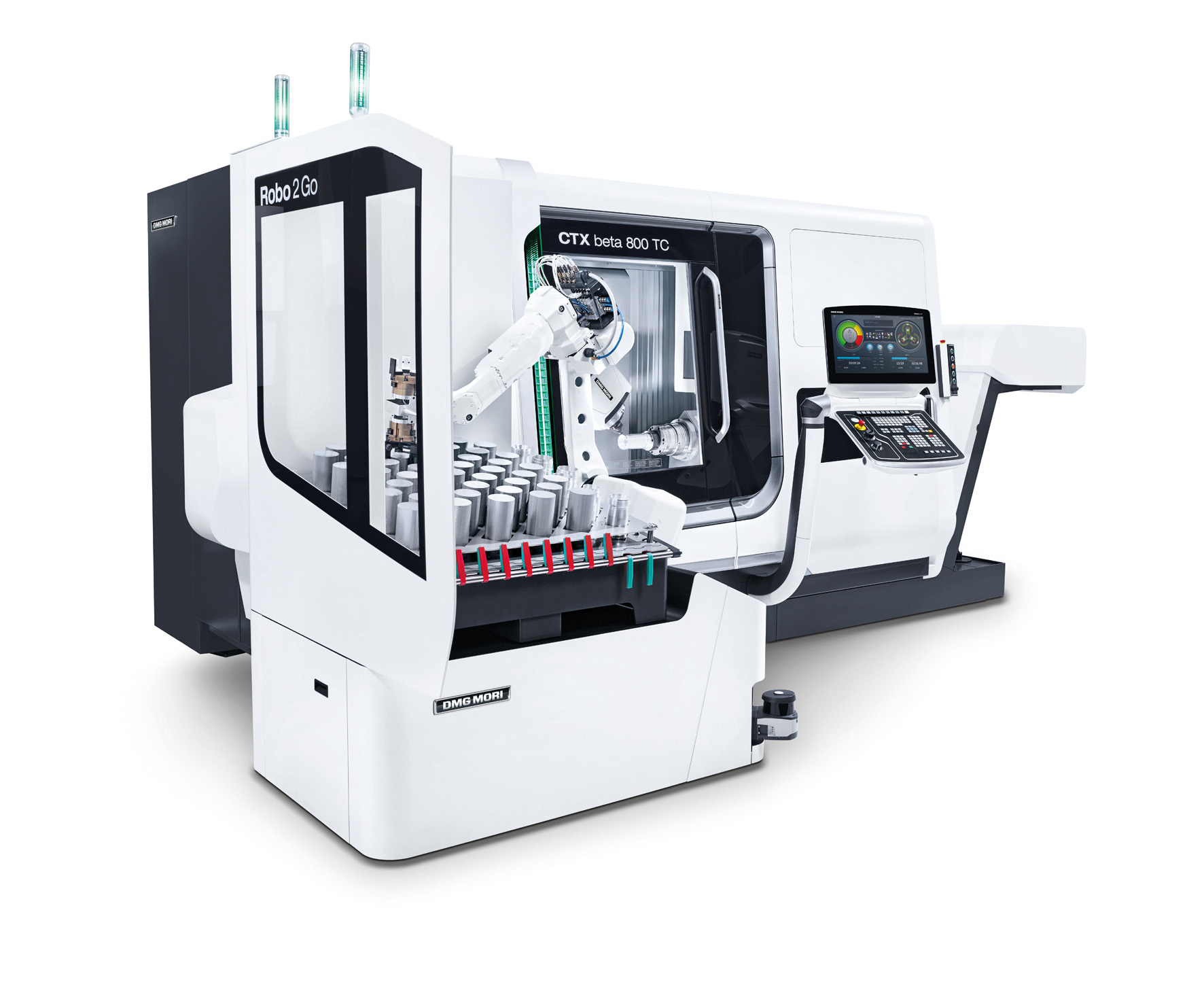

Image 1:

Robo2Go is designed for mobile use with up to four lathes.

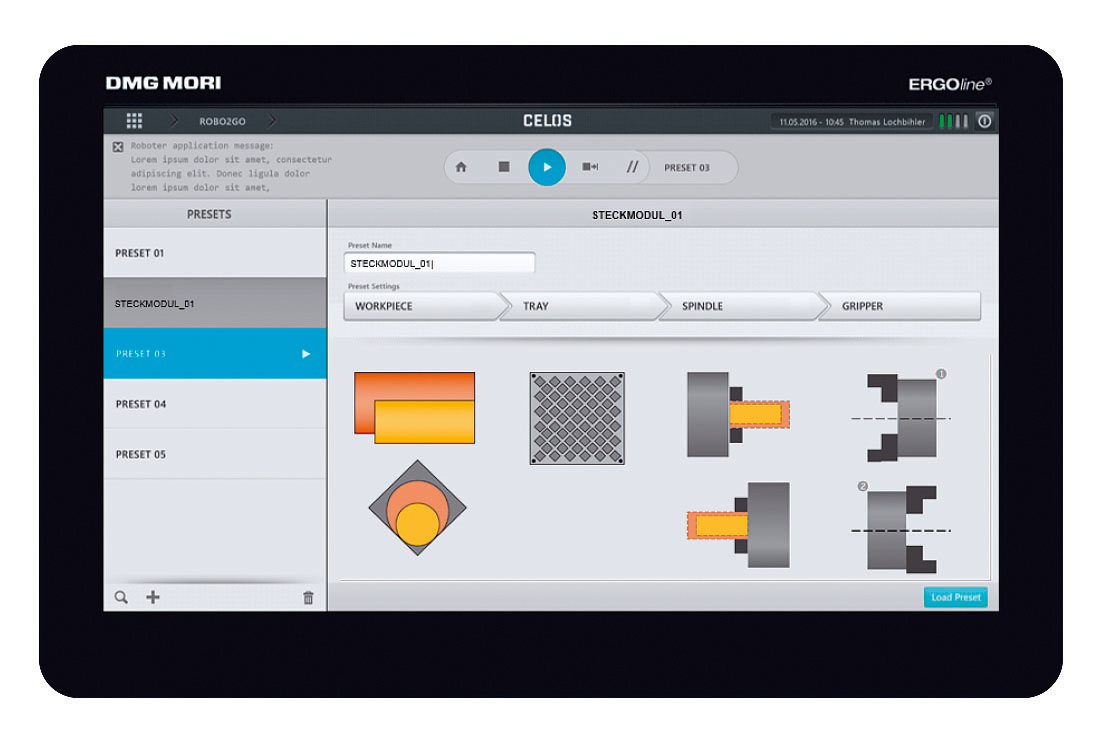

Image 2:

The Robo2Go is programmed via a special Robo2Go App.

Image 3:

All the operator has to do is enter the dimensions of the workpiece, the chuck and the gripper, then select one of the pre-defined arrangements of the workpiece tray and finally start the automatic process.