Chinese companies have generally been making headlines in Europe by acquiring traditional brands and technology companies. The laser start-up XLase GmbH from Hamburg, on the other hand, aims to make Chinese technology for laser material processing popular and successful in Europe and especially in Germany.

Well aware of the demanding customer group and the competence of established competitors, XLase GmbH relies on the technological and mechanical engineering excellence of the Chinese HSG Laser Group as a parent company and on a consistent strategy based on three strategic pillars:

Customer-oriented and sustainable

“We are well aware of our role as a newcomer in a competitive market”, emphasized Thorsten Frauenpreiß, Managing Director, at the first presentation of the young XLase GmbH in Hamburg. “But we also know what we are capable of doing. And we are convinced that a better solution can outperform competition in any market in the world at any time.” And it is precisely this opportunity that, together with the sales and service partners and on the basis of the gradual expansion of presence and performance, they now want to make consistent use of.

Thorsten Frauenpreiß knows exactly where to start. Looking back on decades of experience working for a leading laser manufacturer, he is well acquainted with the business and its customers. He is also aware of the excellent “market companions”, as he calls the competitors. And above all, he knows that a lot of structural and informal persuasion will be necessary to be perceived as a supplier of first-class machines for laser material processing and to subsequently be successful. In addition to XLase GmbH’s new presence in the market, this requires customer and partner orientation, sustainability and above all patience, says Thorsten Frauenpreiß.

Start-up with Chinese roots

Foshan Beyond Laser Technology Co, Ltd as parent company of XLase GmbH is also aware of the challenges. Better known by the group brand HSG Laser, the company has installed more than 15,000 laser systems worldwide since its foundation in 2006. The majority of them, based on tradition, still use CO2 lasers. Today, however, the fiber laser dominates the international business – both in laser cutting machines for flatbed and hybrid sheet metal, tube and profile processing as well as in multi-axis tube and profile processing systems.

The current production capacity amounts to around 2,000 laser systems. On this impressive basis, HSG Laser is planning to generate sales of around EUR 180 million in 2018. Of this, a high single-digit percentage will flow directly back into research and development, as Frauenpreiß underlines.

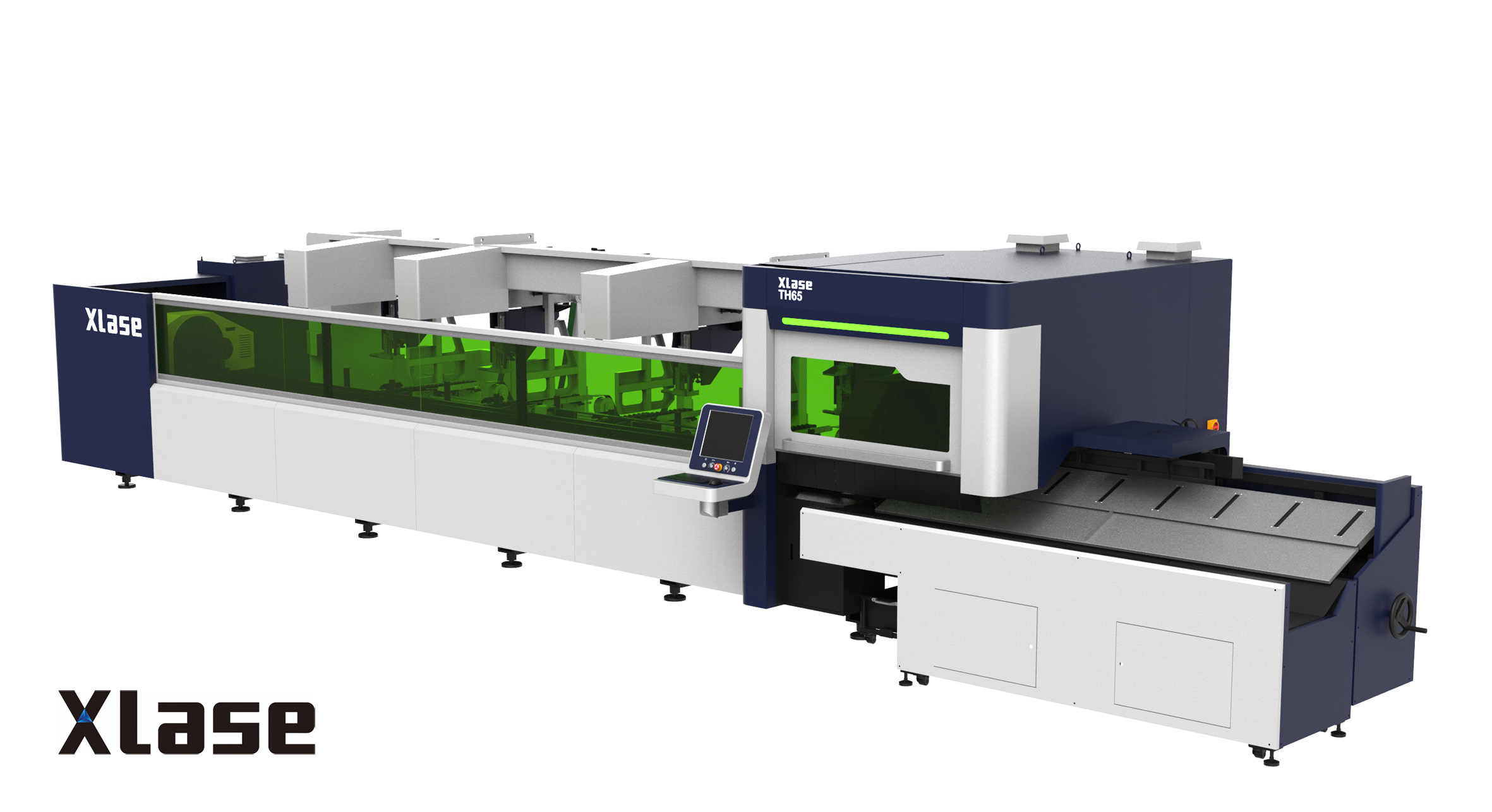

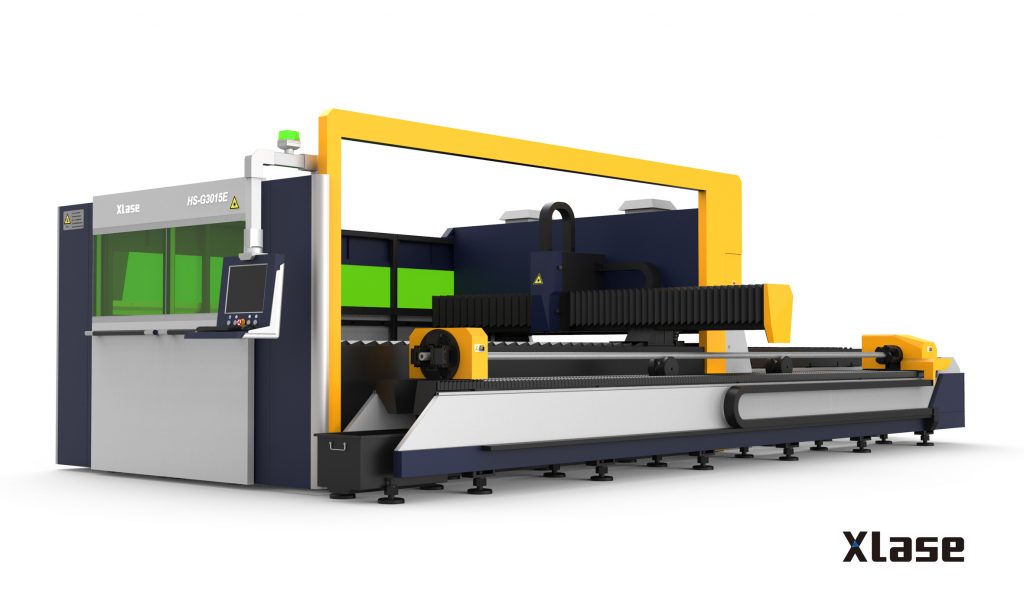

XLase: The high-tech brand for Europe

The founding of XLase GmbH in Hamburg marks a technological paradigm shift for the HSG Group in addition to the market-side aspects. XLase is to be built up as a high-end brand both carefully and consistently in order to meet the requirements of the European market better than they have ever been met before. To this end, HSG will systematically increase investments across their entire product portfolio. In addition to the quoted flatbed and hybrid laser systems and multi-axis multi-machines for sheet metal, tube and profile processing, the overall product range also includes laser robots and automatic production lines in laser power classes up to 15 kW.

Press release from XLASE GmbH