How do thermoplastic tapes reduce costs and increase performance of injection molded parts?

AZL Aachen GmbH in cooperation with the Institute of Plastics Processing (IKV) in Industry and the Skilled Crafts at RWTH Aachen University and the Aachen Center for Integrative Lightweight Production (AZL) of RWTH Aachen University

The AZL and the IKV are jointly developing scenarios with companies on how thermoplastic tapes can be increasingly used in the production of injection molded parts. Medium-sized injection molders, tape manufacturers, machine and tool builders as well as OEMs and Tier 1s are actively involved in the development and benefit from the results. The AZL and the IKV invite interested companies to take part in the joint study and the kick-off event during Fakuma 2018 on October 18th, 2018.

As local reinforcements, thermoplastic tapes enable to improve product properties of injection molded parts and at the same time to save costs due to an efficient use of materials: Increased stiffness and strength, higher surface hardness and improved optics offer small and medium-sized injection molders in particular product advantages for conventional injection molded parts. However, the majority of injection molders use thermoplastic tapes and their potential only occasionally.

Involving Injection Molders, Tape Manufactures, Machine and Tool Builders and OEMs and Tier 1s

The experts at RWTH Aachen University are working on a systematic overview of injection molding applications that are particularly suitable for being optimized with the use of thermoplastic tapes. The focus is particularly on conventional injection molded parts and not exclusively on typical lightweight applications. Another important result of the project will be a comprehensive documentation of the state of the art of relevant methods and technologies for component development and production. Through the active involvement of the entire supply chain, all companies involved will benefit from the knowledge and exchange generated: Development and manufacturing processes will be analyzed and developed that help injection molders in particular to use thermoplastic tapes in their production and to evaluate the potential of the technology. Tape manufacturers and machine and tool builders will gain insight into the requirements and challenges of using thermoplastic tapes from the perspective of processors. OEMs and Tier 1s benefit from the direct exchange with suppliers for communicating their needs and requirements and jointly evaluating applications.

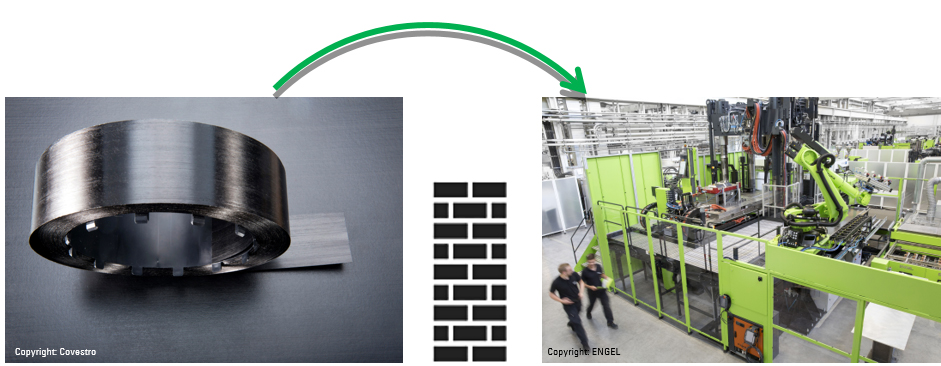

Picture 1: Thermoplastic Tapes offer great potential for injection molded parts. AZL and IKV together with more than 20 companies are developing a guideline for bringing thermoplastic tapes in injection molding processes. Copyright: Covestro/ENGEL

Six Months and three Phases leading to a Guideline

After a classification of development processes of injection molders as well as identification of applications, the 6-months study will lead to recommendations for actions: Business cases for hybrid thermoplastic parts will give concrete examples for parts. Recommendation for action to overcome technical and organizational barriers will be given together with a practical guide including guidelines for project initiation, design, manufacturing and planning.

injection molders, tape manufactures and compounders, machine and tool builder and engineering providers as well as OEMs and Tier 1s are invited to join the study which will start on October 18th, 2018 during Fakuma in Friedrichshafen.

More details

About the Aachen Center for Integrative Lightweight Production (AZL) of RWTH Aachen University and AZL Aachen GmbH

The Aachen Center for Integrative Lightweight Production (AZL) of RWTH Aachen University is specialized in research and development of lightweight products, materials, production processes and systems focusing on integrated and combined process chains and multi-material systems.

As a service provider partnering with companies in the field of lightweight production technology, AZL Aachen GmbH provides industrial services in the areas of engineering, consultancy and project management, networking and business development. With the AZL Partnership, AZL Aachen GmbH together with the AZL of RWTH enables the close cooperation between the lightweight industry and nine research institutes of RWTH Aachen Campus along the whole value chain. The AZL Partner Network consists of more than 80 industrial partners from 21 countries representing the entire lightweight production value chain.

www.azl.rwth-aachen.de

www.lightweight-production.com

About the Institute of Plastics Processing (IKV) in Industry and the Skilled Crafts at RWTH Aachen University

The Institute of Plastics Processing (IKV) is Europe’s leading research institute in the field of plastics technology. IKV develops solutions for future-oriented technologies in plastics processing and is closely working with a 290 or so international member companies, most of them small and medium-sized companies, who benefit directly from the research work at IKV and secure their competitiveness in this way.

In the field of injection molding, the IKV draws on more than 60 years of expertise. In addition to standard processes, special processes such as micro injection molding or the encapsulation of inserts, such as functional metal sheets or thermoplastic composite sheets and tapes, are also used. In addition to process development, current investigations also focus on tool technology and semi-finished product handling.