Lossburg, 2/7/2019

On 25 and 26 June 2019, Arburg hosted the second “Packaging Summit”. The event – which was attended by around 120 guests from all over the world – was conceived to bring together leading experts from industry, research and professional associations, providing a platform for sharing knowledge on trends, resource efficiency and the circular economy in the packaging sector. Participants were impressed by the varied programme of expert talks, innovative live demonstrations and excellent networking opportunities.

The 2019 Packaging summit focused on the currently discussed topic of plastics. “At Arburg, we’ve been looking closely at the topics of resource efficiency and the circular economy for some time now. We have understood the problem and acknowledged its scale, and are doing everything we can to contribute to the solution”, explains Gerhard Böhm, Arburg’s Managing Director Sales. He concludes with a positive outlook for the future: “At the two-day event, we collaborated with well-known experts to explain and discuss how the circular economy can be put into practice in the packaging sector. We demonstrated how the plastic industry is tackling the challenges it faces and showcased some of the resource-efficient solutions and innovations we are planning, both now and in the future, to help the industry on its journey towards a circular economy.”

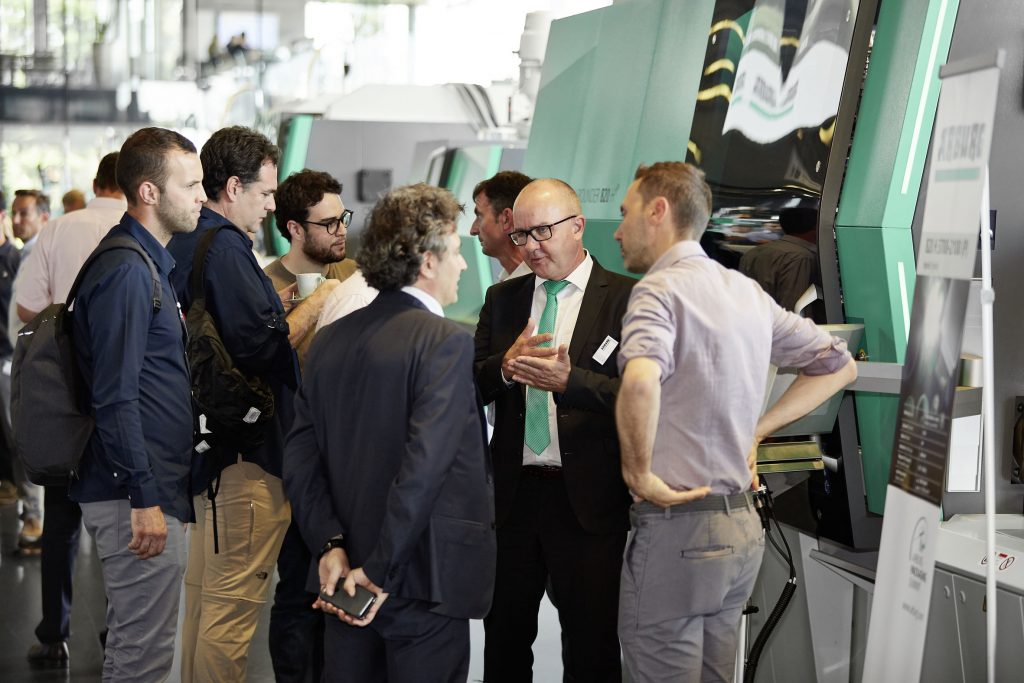

In addition to expert talks, the programme for the Packaging Summit 2019 also included live demonstrations and opportunities to chat to experts like Reiner Schmid (second from right), Application Manager Packaging at Arburg.

The entire value creation chain explained

The event programme included more than a dozen expert talks, each focusing on different aspects of packaging technology. Speakers from BASF, Borealis and Henkel showcased new materials and talked about what their companies are doing to route plastic back into the value creation chain and process recyclable materials. Arburg and its tool partners Stackteck and Foboha presented innovative processes, trends and machine technology designed specifically for the packaging sector. IML expert Verstraete demonstrated how invisible watermarks can be used to label plastic packaging with a “Digital Recycling Pass” so that it can be accurately sorted for recycling. Erema presented a number of its pioneering recycling projects, while Global Flow focused primarily on the disposal and re-use of secondary raw materials. Thorsten Kühmann and Dr Rüdiger Baunemann were also at the event to represent the Mechanical Engineering Industry Association (VDMA) and Plastic Europe Germany. The industry experts spoke about the challenges facing the sector in the future from the perspective of their respective organisations.

Panel Discussion, Gerhard Böhm (ARBURG GmbH + Co KG), Thorsten Kühmann (VDMA), Mandred Hackl (EREMA Group GmbH), Prof. Dr. Hans-Josef Endres (IFBB), Philip Knapen (Borealis)

Live demonstrations complement programme of talks

In the breaks between the talks, attendees had ample opportunity to see selected packaging applications in action in live demonstrations. An electric Allrounder 520 A with 1,500 kN of clamping force was on hand to produce standard PP coffee capsules with a 0.02 mm barrier layer, while a hybrid Allrounder 920 H with 5,000 kN of clamping force and a 48-cavity mould manufactured coffee capsules from an organic material. Two hybrid machines in Packing version demonstrated high-performance packaging technology applications: An Allrounder 820 H with 3,700 kN of clamping force and the optional “thin-walled part” specification produced four IML cups in a cycle time of just 4 seconds. A hybrid Allrounder 630 H with 2,300 kN of clamping force and the optional “closures” package produced 48 drinks container closures in a cycle time of 3.3 seconds. In his talk, Reiner Schmid, Application Manager Packaging at Arburg, explained how these machines and the appropriate mould technology can be used to establish sustainable processes in injection moulding. He reported that machinery was increasingly moving towards direct measurement of internal pressure and temperature and mould breathing via inductive position sensors, which will optimise the filling process and product quality – factors that are of particular importance for new and recycled materials.

International industry meeting in Lossburg: The Arburg Packaging Summit 2019 hosted over a dozen well-known speakers from industry, research and professional associations. Arburg partners Juliane Hehl (right) and Renate Keinath (left) also participated in the event.

New solutions for the circular economy

One of the highlights of the Packaging Summit was the final panel discussion presented by Guido Marschall from Plas.TV. Gerhard Böhm (Arburg), Thorsten Kühmann (VDMA), Manfred Hackl (Erema), Prof. Dr. Hans-Josef Endres (IfBB Institute for Bioplastics and Biocomposites, Hannover University of Applied Sciences and Arts) and Philip Knapen (Borealis) were discussing the current situation of the packaging industry, the findings obtained during the event and future tasks. The experts agreed in the importance of co-operation between all those involved in the value-added chain. Gerhard Böhm also pointed out how Arburg is pooling its activities around the topic of resource efficiency and circular economy with its new “Arburg Green World” program. Examples of these will be presented together with partners at the K 2019 trade fair.

Packaging Summit brings experts together

For Bertram Stern, Sales Manager of Packaging at Arburg, the Packaging Summit was an all around successful event that not only demonstrated the challenges but also in particular the new opportunities for the packaging industry: “Manufacturers of injection moulding machines, moulds and materials, as well as recycling experts, must all work together along the entire value chain. At this event, it was clear for all to see that the spirit and will to do so exists. Only by working together will it be possible to develop new solutions and ensure that valuable used plastics can be recycled and efficiently re-purposed in the manufacture of new products.”

About Arburg

The German family-owned company Arburg is one of the world’s leading manufacturers of plastic processing machines. The product portfolio encompasses Allrounder injection moulding machines with clamping forces of between 125 and 6,500 kN, the Freeformer for industrial additive manufacturing and robotic systems, customer- and industry-specific turnkey solutions and further peripheral equipment.

An international sales and service network ensures first-class customer support at a local level: Arburg has its own organisations at 34 locations in 26 different countries; together with its trading partners, it is present in more than 100 countries. Its machines are produced exclusively at the parent company in Lossburg, Germany. Of a total of roughly 3,000 employees, around 2,500 work in Germany. About 500 further employees work in Arburg’s organisations around the world. Arburg has triple certification according to ISO 9001 (quality), ISO 14001 (environment) and ISO 50001 (energy).

Further information about Arburg can be found at www.arburg.com