Sumitomo (SHI) Demag presents a fully optimised and automated LSR production cell developed for tight tolerance automotive applications in collaboration with partners dedicated to achieving the highest LSR processing stability.

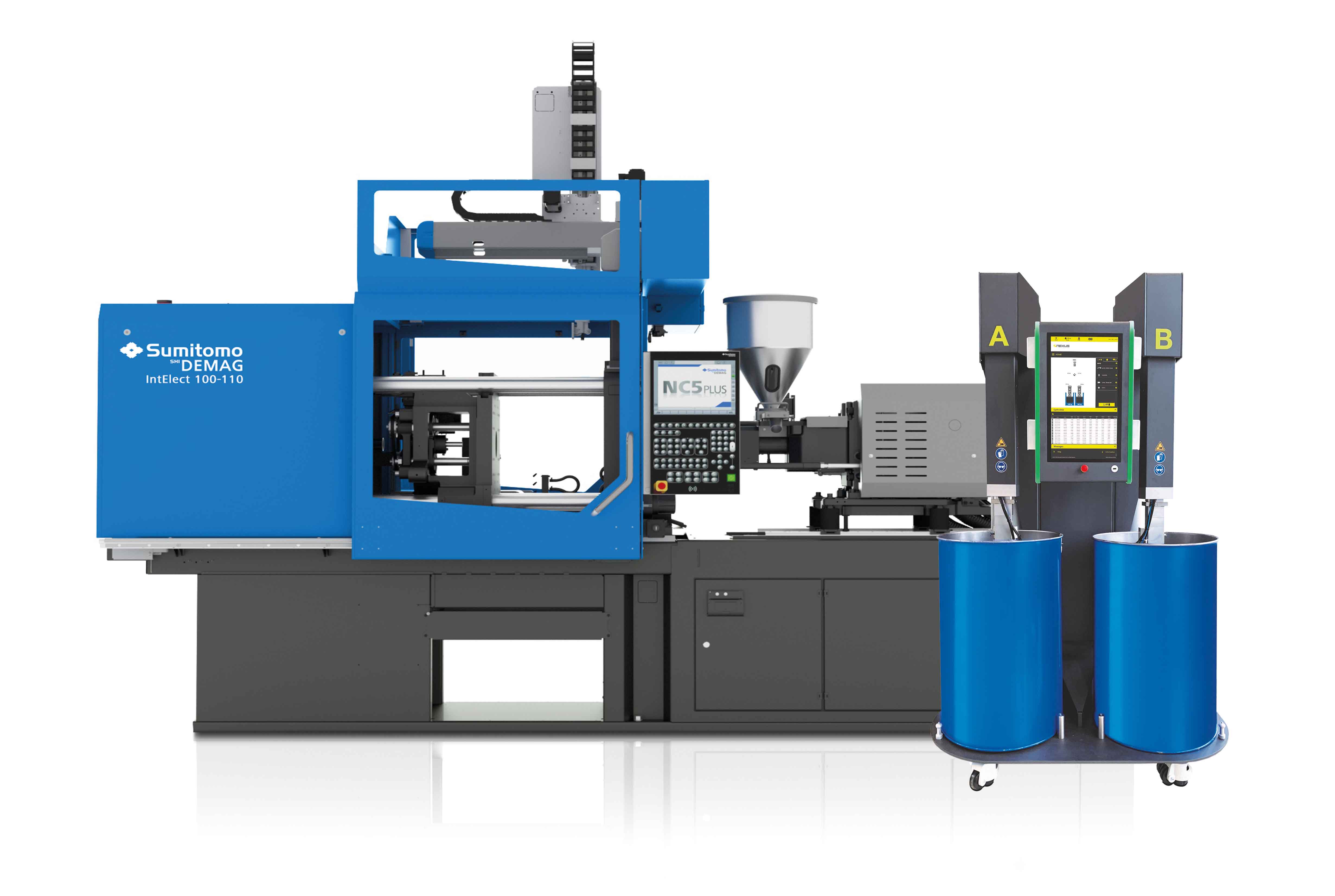

Schwaig, October 2021 – Sumitomo (SHI) Demag Plastics Machinery GmbH, Schwaig, Germany, will unveil a state-of-the-art elastomer injection moulding system at Fakuma 2021. For its inaugural presentation on the global stage, the LSR package features a fully automated Nexus metering system on an all-electric IntElect 130/520-450. All integrated seamlessly with the company’s new own-branded SAM-C kinematic robotic system and meeting the new 2021 OPC-UA 40082-3 standard for LSR dosing systems to optimise and control and processing stability on automotive applications.

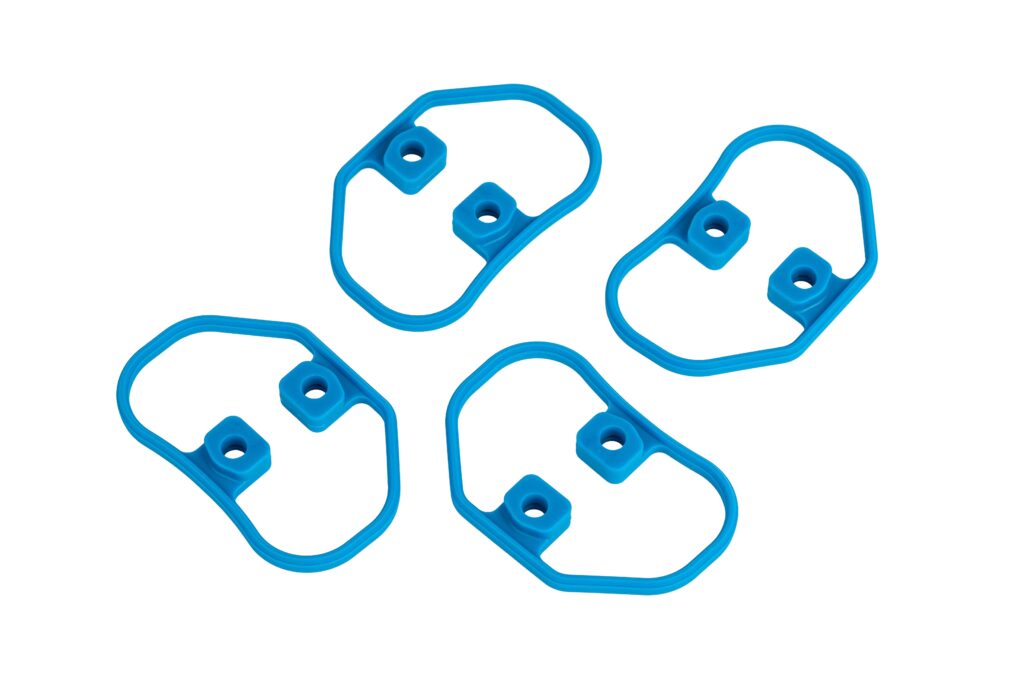

Demonstrating the production of a complex freeform automotive axial seal on Sumitomo (SHI) Demag’s LSR exhibit, the seal is designed to be moulded using a ‘direct gate’ without material closure. Describing the processing challenges a high spec component like this presents, Henrik Langwald, Director Automotive & Electronics explains: “The sealing lip must be completely pronounced to offer full functionality. We are setting a new benchmark to repeatably mould the tightest tolerances in 16 cavities, burr-free, with no conversion,“ he succinctly sums up.

Produced using a Nexus two-plate tool, a retainer keeps the seal component stable on the ejector side. The newly launched SAM-C ‘handle & place’ cartesian robot developed in-house by Sumitomo (SHI) Demag then removes and stores the part. This involves working with a cold runner needle closure system and direct injection. The tool concept includes interchangeable inserts, ensuring the highest product flexibility. As a result of the high precision processing, stability is maintained to deliver the optimal sealing requirements so critical for automotive safety.

Sumitomo (SHI) Demag will be demonstrating the production of a complex freeform automotive axial seal

Aligned in efficiency and processing stability

An important component of the innovative production solution is the ServoMix Z200 metering system from Nexus. “The system is unsupported and the barrel can be swiftly and safely changed in less than five minutes from an angle of up to 104 degrees,” reports Langwald. This provides easy and faster access for cleaning and maintenance, as well as helping to eliminate human errors.

Additionally, the new generation metering system also features numerous interfaces, including the TrueFlow Nano colour control to ensure precise dosing of colour additives, as well as a calibration function. Material flows are measured in microlitres for major components, with additives measured in nanolitres.

OPC-UA-ready, the flow-meter design features a quick-change pump body with measuring cells located directly on the pump body. “No additional hose connections are required,” notes the expert highlighting the relevance of this to the medical sector. Another advantage of this design is faster cleaning of the injection moulding screw. Additionally, all new dosing devices now feature the newly-released OPC-UA interface, directly linking metering measurement data of with the IntElect 130/520-450 processing data, ensuring a fully traceable and stable production process. “The timeshot or balancing system in the mould can be mirrored by the injection moulding machine via VNC,” adds Langwald.

Compared to hydraulic systems, the newest ServoMix models report low energy consumption. They work more sustainably, and there is much less waste and material consumption. By regulating the flow rate according to actual requirements, users can save up to 70 percent in energy. The material loss due to residual quantities in the barrel amounts to less than 0.3%. “Overall, the systems are more environmentally friendly,” states Langwald, referencing the company’s “Act! Sustainably” corporate mission and CSR statement which underpins Sumitomo (SHI) Demag‘s efforts and future machinery and equipment innovations.

IntElect delivers the most sustainable combination

The Nexus equipment ideally complements the extremely economical IntElect 130/520-450, which is specially configured to LSR processing. Geared towards top dynamics, the IntElect’s drive system developed in-house combined with frequency inverters and the entire servo motor control makes it one of the most efficient injection moulding machines on the market.

“Compared to conventional all-electric systems, the IntElect requires up to 20 percent less energy,” states Langwald. A higher availability of around two percent combined with dynamic, precise and parallel movements delivers up to ten percent higher production output. Additionally, the precision and processing repeatability prevents defects and rejected parts. “This in turn significantly increases output and at the same time reduces costs,” adds Langwald

According to the automotive and electronics director, the exhibit axial seal application cycle time will run between 30 and 35 seconds using the maximum clamping force for thick-walled seals. The IntElect’s stiff tool platen design provides optimal support of the tools ensuring more balanced pressure distribution via the clamp force . Further features are the highly dynamic movement of all axes and the highest precision on the injection and closing axes to support ventilation. The adaptable sequence programming accommodates flexible machine processing requirements. Additionally, the IntElect LSR unit is equipped with an extended process control, including feed pressure monitoring and vacuum build-up time.

Adding Industry 4.0 control, monitoring and integration capabilities, the IntElect’s OPC-UA interface also includes the Euromap’s new 40082-3 standard for LSR dosing systems introduced on 1 June 2021. “Naturally, the Nexus ServoMix systems are integrated too, enabling the moulding machine and mixing and dosing system to communicate seamlessly via one platform,” explains Langwald. He also references the “myConnect” web-based software solution developed in-house by the Sumitomo (SHI) Demag team. This central platform gives customers direct access to a wide range of fully networked support services, helping to better manage production inefficiencies, reduce costs and total cost of ownership, troubleshoot errors and minimise downtime.

For the exhibit seal application, a silicone rubber – Elastosil LR3003/50 from Wacker Chemie AG, Munich – has been selected. With a temperature range of -55°C to +210°C and a Shore A hardness of 50, it is ideal for manufacturing the freeform seal. Explaining the rationale for this material choice, Langwald expands: “In addition to the automotive industry, freeform seals are also used for electronic components in consumer goods and electronic products. Silicone rubbers are heat-resistant, retain flexibility when cold and shouldn’t age when exposed to UV and air etc. They are easy to process and have good mechanics that remain stable over a wide temperature range. Additionally, they are tasteless and biologically inert.”

New SAM-C robot ideal for high-care LSR moulding

Another highlight integrated into the automotive LSR exhibit showcase is Sumitomo (SHI) Demag’s first own-label, in-house developed, SAM-C (Sumitomo Demag. Automation. Machine – Cartesian) robot series. Designed specifically for injection moulding machines with clamping force sizes between 50 and 500 tons, and for standard applications with cycle times of 10 seconds and higher, the LSR exhibit demonstrates the importance of using robotics to eliminate component contamination and consequent product impairment. In this instance the sealing function.

“With SAM-C, we have succeeded in engineering the smallest automated injection moulding production cell comprising robot and material handling technology,” notes Jürgen Schulze, Director Automation, describing the “handle&place” solution.

Highlighting further advantages of this exciting in-house automation launch, Schulze explains: “We offer high system availability with minimal repair and maintenance work, thanks to Sumitomo (SHI) Demag’s in-house servo motor technology and low-maintenance drive and guide technology. With the corresponding vacuum technology, the systems also deliver significant energy-savings.”

Customers benefit from process and system technology from a single supplier source, complete with hardware and software control integration of robot technology into the injection moulding unit and production-optimised robotic mechanics fully customised to Sumitomo (SHI) Demag machines. “Key advantages include an attractive price-performance ratio incorporating full injection moulding and automation, including CE marking conformity,” says Schulze.

With the IO-Link communication system, intelligent sensors and actuators can be connected to the automation system. This means the SAM series fully meets future Industry 4.0 and Smart Manufacturing requirements.

Sumitomo (SHI) Demag Plastics Machinery GmbH

Sumitomo (SHI) Demag has shaped the development of the plastics industry from its very beginning. As a specialist for injection moulding machines for plastics processing, Sumitomo (SHI) Demag and its Japanese parent company are leading the industry.

The global development and production network of Sumitomo Heavy Industries and Sumitomo (SHI) Demag is comprised of four facilities in Japan, Germany and China with more than 3,000 employees. The product portfolio includes all-electric, hydraulic and hybrid injection moulding machines with clamping forces of between 500 kN to 15 000 kN. With more than 149,000 installed machines, Sumitomo (SHI) Demag is present in important global markets and ranks among the largest manufacturers of injection moulding machines in the world.

At Sumitomo’s headquarters in Chiba, Japan, the company manufactures machines with clamping forces in the small to medium range. Nearly 95 % of all delivered machines are equipped with an all-electric drive concept. Sumitomo (SHI) Demag’s German facilities in Schwaig and Wiehe produce the Systec Servo range with hybrid drive as well as the El-Exis SP and Systec SP range of high-speed, high-performance machines. The all-electric IntElect range for international customers is also being produced in Germany.

As early as 1998, Sumitomo (SHI) Demag set up its first production site in Ningbo/China. In 2015, the Chinese subsidiary Demag Plastics Machinery (Ningbo) Co., Ltd. installed a new facility with a 13,000 m² floor space. It is earmarked for the production of the Systec C range with clamping forces of between 500 and 10,000 kN for the Asian market.

In addition to injection moulding machines, Sumitomo (SHI) Demag offers customised and standardised systems for the part handling automation, technical and process solutions for special applications, tailored services and service concepts as well as a range of financial options to support investment in injection moulding machines.

With its comprehensive sales and service network of subsidiaries and agencies, Sumitomo (SHI) Demag is present in all major markets.