Arburg calculates meaningful product carbon footprints

Arburg has been working intensively on the topic of sustainability and resource efficiency for a very long time. As a supplier of Allrounder injection moulding machines, the machine manufacturer is increasingly active in evaluating climate protection activities along the entire value chain for its customers. On the basis of ISO TS 14067:2018, a standard that defines a product’s greenhouse gas emissions or product carbon footprint (PCF), Arburg has investigated how the PCF and specific energy requirements of its injection moulding machines can be calculated.

Under the European Union’s Green Deal, the reduction of the carbon footprint of companies and their products is being strongly promoted. To be able to meet the strict legal requirements and achieve climate-neutral production by 2050, companies will have to significantly increase energy and resource efficiency in the future. Accordingly, sustainability is currently an important strategic issue for many European plastics processors.

Enshrined in law: Carbon neutrality in Germany by 2045

The German Climate Protection Act goes one step further and calls for a 65 per cent reduction in CO2 emissions by 2030 and carbon neutrality by 2045. The internationally recognised standard for CO2 accounting – the Greenhouse Gas Protocol – considers different emission areas (scopes). Injection moulding machines are Scope 3 assets, which include indirect emissions from upstream and downstream business processes. As a machine manufacturer, Arburg is actively and comprehensively involved in carbon accounting in order to provide reliable and comparable indicators and meet the ambitious climate targets. This is also evidenced by its above-average “B” score in the Carbon Disclosure Project (CDP).

PCF – Product Carbon Footprint

In contrast to the corporate carbon footprint (CCF), which is calculated for an entire company on an annual basis, the product carbon footprint (PCF) includes the quantities of greenhouse gases emitted and removed over the entire service life of a product. Expressed as CO2 equivalent, the PCF is an important indicator in the life cycle assessment. The guidelines for quantification and reporting are provided by the international standard ISO TS 14067:2018.

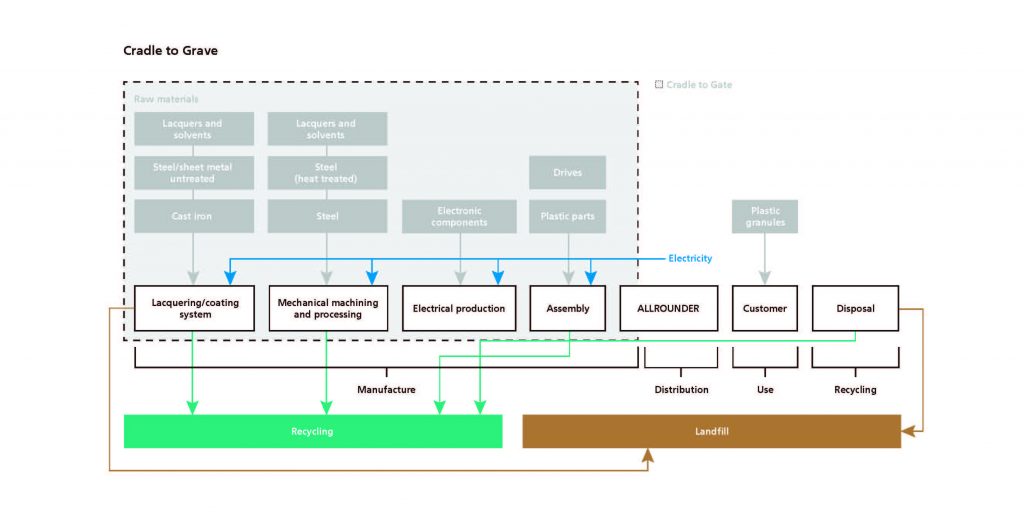

The first relevant question for injection moulders is the carbon footprint with which the machine produced by the manufacturer arrives at the plant. In its “cradle to gate” analysis, Arburg draws the associated system boundary from raw material extraction through the manufacturing phase to the factory gate. However, this period only accounts for around five per cent of CO2 emissions. Over the entire product life cycle (“cradle to grave”), most of the PCF is generated during the use phase at the customer’s premises, in addition to emissions during distribution and disposal.

Arburg records CO2 emissions up to the finished injection moulding machine in four process steps: painting or coating, mechanical machining and processing, electrical production, and assembly. The raw materials used and the respective electricity requirement can be assigned to this operational sequence and the other phases in the product life cycle (Fig. 1).

Fig. 1: In the “cradle to gate” analysis, Arburg accounts for the CO2 emissions of its Allrounder injection moulding machines from the raw materials used and the manufacturing process to delivery.

Raw material-related CO2 emissions

The parts list of an injection moulding machine can consist of up to 11,000 individual items, down to the individual screw. For better manageability, Arburg groups raw materials into eight material groups. Accordingly, an Allrounder consists of more than 55 per cent plastic-coated cast iron, and another 35 per cent or so of steel and sheet metal (hot-treated, painted, plastic-coated, or untreated). Plastic components, drives and electronic components account for only about seven per cent of the total weight.

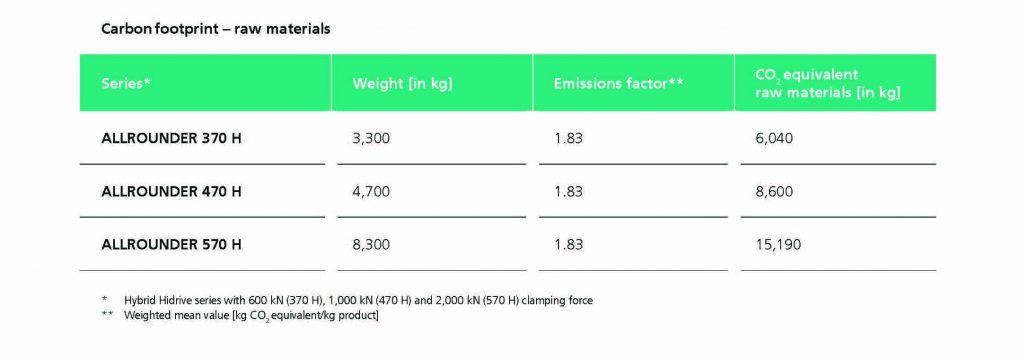

The material groups differ significantly in terms of the CO2 emissions generated during their production. However, a weighted mean value can be determined along the lines of the distribution. This so-called emissions factor is around 1.83 [kg CO2 equivalent per kg product] for an Allrounder. The CO2 equivalent for the complete injection moulding machine thus corresponds to the emissions factor multiplied by the product weight specified in the data sheet (Fig. 2).

Fig. 2: To calculate the CO2 emissions of an Allrounder in terms of raw materials, its net weight is simply multiplied by an emissions factor of 1.83 as determined by Arburg.

A hybrid Allrounder 570 H with a clamping force of 2,000 kN and a net weight of 8,300 kg therefore causes raw material-related emissions of around 15,190 kg of CO2 during its manufacture. For a 3,300 kg size 370 Allrounder with 600 kN clamping force, the CO2 equivalent is around 6,040 kg.

Electricity-related CO2 emissions during production

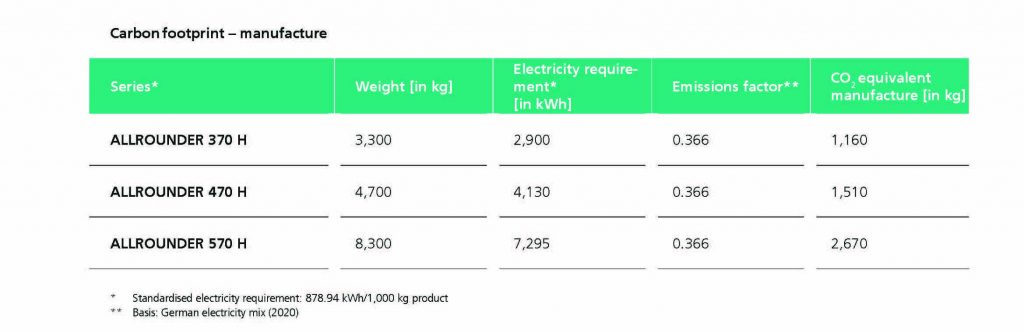

In the manufacturing phase, the electricity requirement also contributes to the PCF. In relation to the year 2020, the basis for standardised calculations is an electricity requirement of 878.94 kWh per 1,000 kg of product and an emissions factor of 0.366 [kg CO2 equivalent per kWh] for the German electricity mix (Fig. 3).

Fig. 3: Electricity-related CO2 emissions in the production of an injection moulding machine can be calculated on the basis of the German electricity mix (0.366 for the year 2020).

On the basis of the German electricity mix, the electricity requirement is 2,900 kWh for the Allrounder 370 H, with a CO2 equivalent of around 1,160 kg. For the Allrounder 570 H, the electricity requirement is therefore 7,295 kWh and the emissions around 2,670 kg CO2.

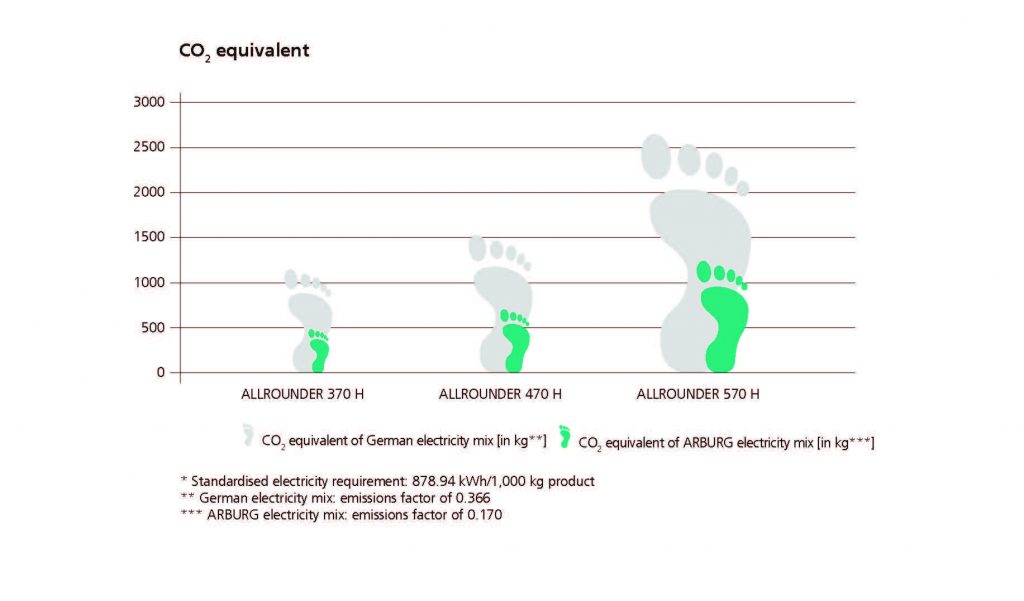

However, this example calculation cannot be applied 1:1 to Arburg, as the company manufactures around 60 per cent of its Allrounder components itself. Arburg makes its products exclusively at its central location in Lossburg, Germany. This involves the use of carbon-neutral renewable energies such as photovoltaics, wind energy and geothermal energy, as well as combined heat and power. Since 2016, electricity purchased regionally has come entirely from ecological sources. This means that the emissions factor for the “Arburg electricity mix” is only 0.17 instead of 0.366. (Fig. 4).

Fig. 4: Arburg relies on a high degree of in-house production depth and sustainable energies at its central manufacturing site in Lossburg. The electricity-related CO2 equivalent of an Allrounder is therefore around 53 per cent lower than the German average.

In concrete terms, this means that the electricity-related CO2 equivalent for the Allrounder 370 H is actually only 490 instead of 1,160 kg, while for the Allrounder 570 the emissions amount to 1,240 instead of 2,670 kg CO2. Due to the high degree of in-house production depth and the sustainable electricity mix, this means that around 53 per cent fewer emissions are produced in terms of electricity during the manufacturing phase of an Arburg injection moulding machine than the German average.

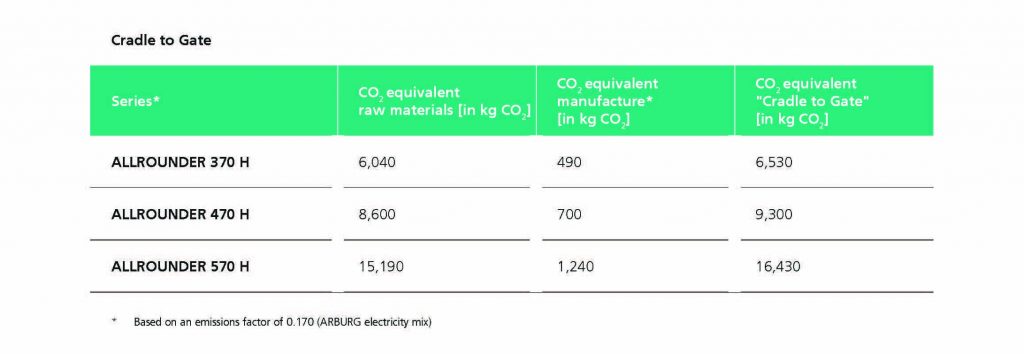

If the raw material and electricity-related emissions are added, the total CO2 equivalent for a “cradle to gate” analysis is 6,530 kg for the Allrounder 370 H and 16,430 kg for the Allrounder 570 H (Fig. 5).

Fig. 5: The carbon footprint (PCF) of the machines up to delivery to the customer is calculated from the sum of the raw material and electricity-related CO2 equivalents.

For comparison: In Germany, each person generates an average carbon footprint of around 12,000 kg per year, depending on factors such as consumption, mobility, housing and nutrition.

Application-related carbon footprint in use

Around 95 per cent of the PCF of an injection moulding machine is attributable to its use phase. How many emissions it actually produces in daily operation depends on a large number of factors. Already during the selection of the plastic, the product design and the construction of the injection mould, important decisions are made. An important application-related parameter here is the specific energy requirement [kWh per kg], which is calculated from power consumption per material throughput. As a rule of thumb, the shorter the cycle time and higher the shot weight, the smaller the specific energy requirement and better the CO2 equivalent.

Machine equipment crucial

A crucial aspect for the specific energy requirement is whether the injection moulding machine has an electric, hybrid or hydraulic drive. Whether one or two-circuit pump technology or hydraulic accumulators are used and options such as servo-electric dosing or ejection are part of the equipment also play a role.

Features that enable simultaneous, dynamic and fast movements and thus short cycle times have a positive effect on the carbon footprint during use. The same applies to the screw diameter and installed power – the greater the shot weight and the smaller the power consumption, the better. In summary: machine equipment that is precisely adapted to the requirements and processes can significantly improve the energy requirement. Arburg supports its customers in this task with a wealth of expertise in application and process technology and exploits the advantages of modular machine technology.

Measuring the energy requirement in accordance with EUROMAP 60.2

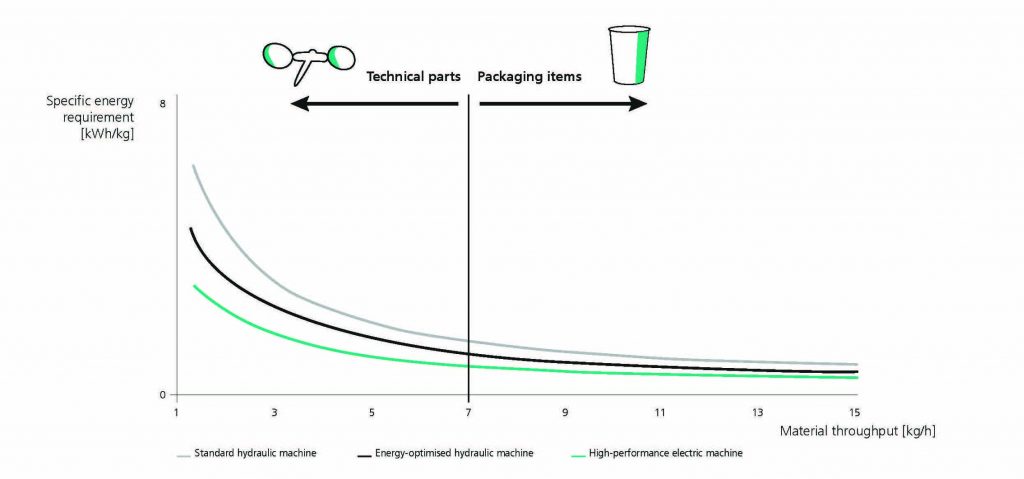

The EUROMAP 60.2 recommendation forms the basis for determining the energy requirements of injection moulding machines in a customer-specific process. To enable an objective comparison of different machine concepts, measurements are taken and documented at average power consumption under uniform specifications over a defined area. The values depend on the machine technology as well as the capacity utilisation and type of application. For example, the specific energy requirement for the production of technical moulded parts in smaller quantities is significantly greater per se than for the production of fast-moving packaging items (Fig. 6).

Fig. 6: The specific energy requirement of an injection moulding machine in the operating phase depends on the equipment, type of application, and material throughput. Generally speaking, the better the machine’s capacity utilisation, the more favourable its carbon footprint.

The measurement results show that, in comparison to standard hydraulic machines, electric machines require around 50 per cent less energy. The lower the material throughput, the more significant the differences. But energy-optimised hydraulic machines can also significantly reduce the carbon footprint.

Application example

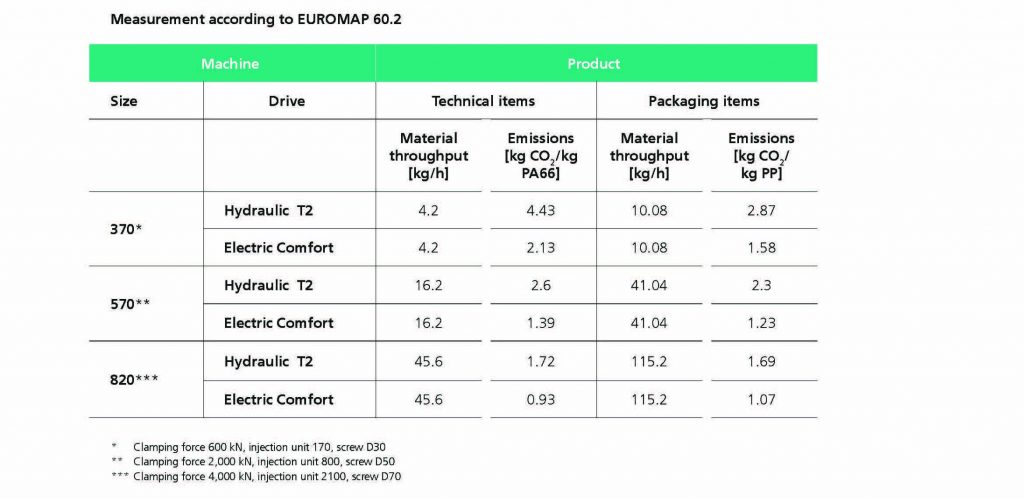

Arburg examined various scenarios as part of a practical application: Hydraulic and electric Allrounders from the S and Alldrive series were used in the three sizes – 370, 570 and 820 – with clamping forces of 600, 2,000 and 4,000 kN. A distinction was made between hydraulic drive systems with two-circuit pump technology (T2) and electric drive systems in the “Comfort” performance variant.

Two items were produced: a technical item made of PA66 (GF30) in a cycle time of 30 seconds at 50 per cent plasticising capacity, and a packaging item made of PP in a cycle time of five seconds at 100 per cent plasticising capacity (Fig. 7). The CO2 emissions were calculated on the basis of the German electricity mix.

Fig. 7: By way of example, Arburg investigated the CO2 emissions of Allrounders in three sizes and two drive types using measurements in accordance with EUROMAP 60.2. One technical part and one packaging item each were manufactured

The electric Allrounder 820 A with a throughput of 115.2 kg/h produced emissions of 1.07 kg CO2 per kg of plastic material while injection moulding the packaging item. The size 370 electric machine emitted around twice as much (2.13) when injection moulding the technical article with a throughput of 4.2 kg/h. With the hydraulic Allrounder 370 S, this value was as high as 4.43.

So much for the sample study. Depending on the case of application, there may be deviations from this. In individual cases, the actual power consumed depends on the duty cycle, capacity utilisation, and efficiency of the connected loads. These factors are in turn influenced by the injection moulding process. However, it can generally be said that the energy requirement for both types of drive decreases as material throughput increases. In any case, an electric machine produces around 50 per cent fewer CO2 emissions. The same result can be seen when the CO2 emissions are calculated consistently on the basis of the material throughput.

The CO2 emissions for the production of the plastic granulate and other loads such as peripheral devices for temperature control of the moulds or hall air conditioning (waste heat and cooling) are not included in this analysis. The energy requirements and thus the CO2 emissions of the peripheral devices increase sharply, especially for technical items, and may even exceed those of the injection moulding machine on a proportional basis. The carbon footprint calculated for a single injection moulded part is another interesting parameter.

Conclusion

An meaningful “cradle to gate” carbon footprint can be determined for injection moulding machines. Raw materials have a roughly tenfold greater impact on the product carbon footprint than electricity consumption during the manufacturing phase. Local supply chains, a high degree of in-house production depth and the use of renewable energies can have a positive impact on the footprint.

The PCF during the use phase depends on many factors. A specific case study is required here. As a rule, the specific energy requirement of an injection moulding machine decreases with its capacity utilisation. In addition, electric machines generate up to around 50 per cent less CO2 emissions than hydraulically driven ones, depending on the equipment and material throughput.

The aim for the future is to be able to calculate a scientifically sound, holistic life cycle assessment for injection moulding machines. This will require a much greater effort. This is precisely what the Institute of Plastics and Circular Economy (IKK) at Leibniz University in Hanover, headed by Professor Hans-Josef Endres, is working on in collaboration with Arburg, among others.

Author: Bertram Stern, Sustainability Manager at Arburg.

About Arburg

German family-owned company Arburg is one of the world’s leading manufacturers of plastic processing machines. Its product portfolio encompasses Allrounder injection moulding machines with clamping forces of between 125 and 6,500 kN, the Freeformer for industrial additive manufacturing and robotic systems, customer and industry-specific turnkey solutions and further peripheral equipment.

An international sales and service network ensures first-class customer support at a local level: Arburg has its own organisations at 34 locations in 25 different countries and, together with its trading partners, is represented in more than 100 countries. Its machines are produced exclusively at the company’s German headquarters in Lossburg. Of a total workforce of over 3,400, approximately 2,850 people are employed in Germany. Over 550 people work in Arburg organisations around the world. Arburg has triple certification, in accordance with ISO 9001 (quality), ISO 14001 (environment) and ISO 50001 (energy).

Further information about Arburg can be found at www.arburg.com