Baumüller will be exhibiting its solutions and systems for Industry 4.0 at the Hannover Messe from April 1-5, 2019 as a specialist for automation and drive technology. In hall 14 at stand H12, Baumüllerwill exhibit smart motor concepts, intelligently integrated drive functions and powerful control platforms at various stations. In addition to systems and components, the companies of the Baumüller Group will present their consultation and engineering services for mechanical engineering and machine operators as well as the complete range of services across the entire life cycle of machines and systems. In this way, visitors to the trade fair stand can find out about the design of new drive systems and the optimization of existing drive systems and the latest tools and software solutions.

Visitors to the trade fair stand can look forward to a tour of the topic of life cycle management, a live demonstration of the new software ProSimulation, a presentation of new motion libraries, a theme park for decentralized drive technology and e-mobility as well as new products, such as the expansion of the water-cooled servomotor series to include small installation sizes.

Baumüller Life Cycle Management

Baumüller is a full service provider and covers both the development and production of components as well as system solutions and countless service services for mechanical and plant engineering as well as for machine operators. Under the motto “Enabling Industry 4.0: Value creation in every phase,” visitors go through each phase of the life cycle while touring the trade fair stand, thereby learning the respective solutions and products for this purpose live using the example of a 6-axis welding robot:

· Technology package – Automation system of the high-performance box-PC b maXX PCC-04 to the high-precision servomotor series DSH1

· Engineering – the integrated Engineering Framework ProMaster for all automation tasks, including the new motion library for multi-axis applications

· Commissioning – Virtual commissioning for quick time-to-market with the new tool ProSimulation

· Production – the optimization tool BAUDIS IoT for predictive maintenance and process optimization offers benefit-oriented Industry 4.0 for production

· Service – Intelligent service concepts, from machine assembly to the global spare parts concept

Faster time-to-market: new ProSimulation software

Virtual configuration and testing of automation systems: The newly developed software ProSimulation will be presented for the first time at the Hannover Messe, allowing customers to easily and immediately enter into the world of simulation. The new tool very concretely simplifies the virtual

design, optimization and commissioning of machines and plants. Depending on the level of experience, customers can either quickly build their own simulations or applications thanks to the base library, or they can import existing software models thanks to the open interfaces.

The advantages of ProSimulation are time and cost savings during development and commissioning, optimization of existing machines and systems as well as the establishment of simulation know-how in the company. ProSimulation extends the range of functions of the ProDrive operating software, which allows for the simple and fast commissioning, parameterization and operation of all b maXX controllers

from Baumüller.

Simple engineering: Expansion of the Motion Control Library to Include Coordinated Motion

Baumüller will present the Engineering Framework ProMaster at the Hannover Messe, which is based on the library concept: In addition to the base library with motion modules as per PLCOpen, Baumüller offers a growing library of specific modules as well as machine modules with comprehensive functionalities for quick and easy engineering. Each machine module is tailored to key machine functions and is optimally adjusted. The base library has now been expanded to include different motion modules for the motion control of up to three motor axes of a system.

Manufacturers who would like to develop multi-axis machines with basic functions such as milling, cutting or even individual motion sequences with little effort will receive a modular automation solution that can be adapted to different applications thanks to the motion libraries from Baumüller. The main advantages of using Baumüller’s machine modules for multi-axis applications are the reduced costs, the simple handling during the project planning and commissioning and therefore the much shorter time-to-market.

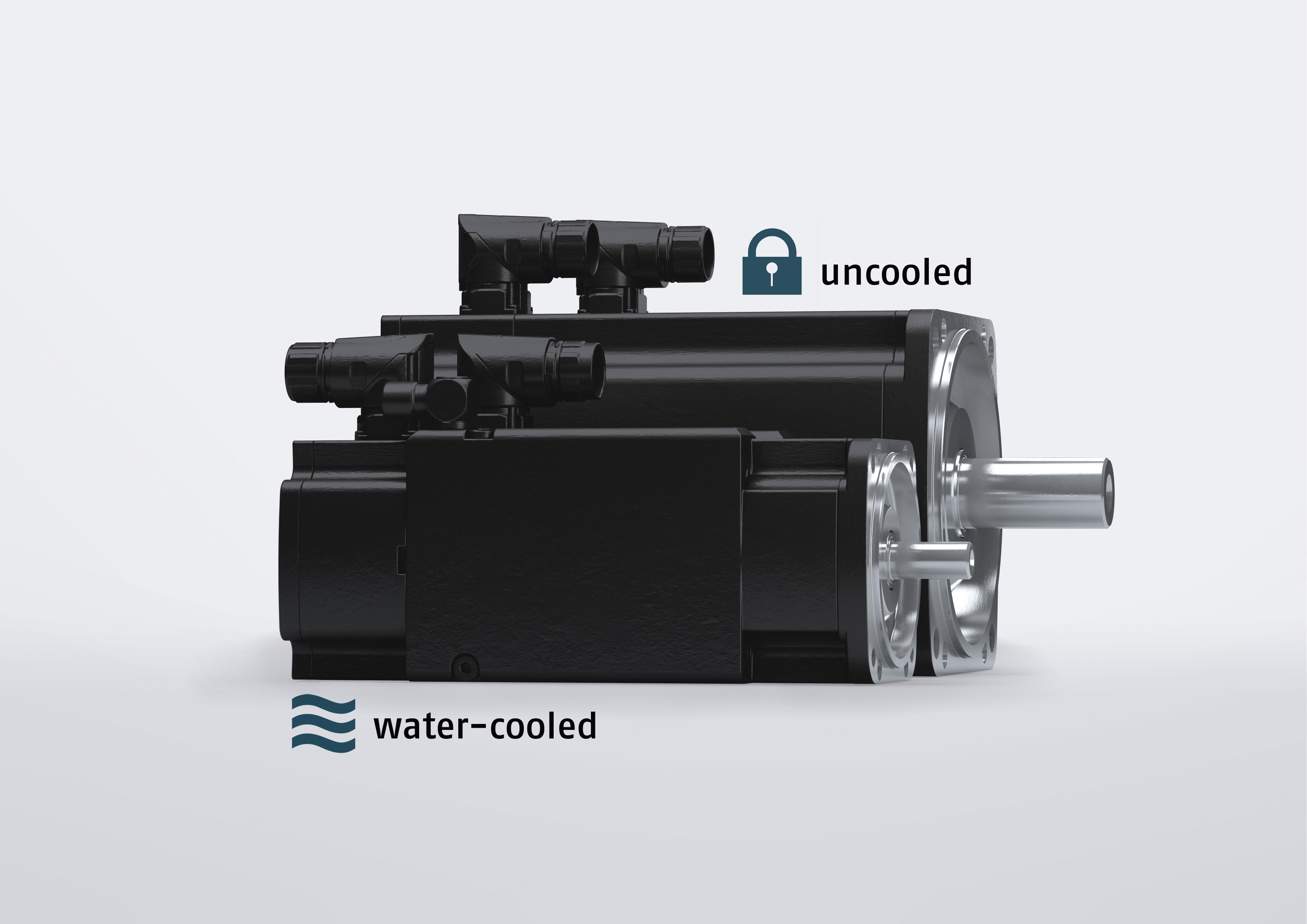

Enhanced performance: Compact Water-Cooled Servomotors

Baumüller is expanding its servomotor portfolio with the water-cooled model sizes 45 and 56. The advantages of water cooling especially come into their own in the small installation sizes with their space-saving installation and simultaneously very high power density. The water cooling makes it

possible for high nominal power motors to be used in a very compact installation space. For mechanical engineers, this means optimal mechanical properties, lower costs and better economic efficiency.

In addition to saving costs, the small water-cooled installation sizes also have other advantages in relation to the installation space: The housing family is identical in design to an uncooled version and thus combines the advantage of maximal cooling with minimum dimensions. Another positive aspect of heat dissipation using the cooling medium of water is that the motors can be placed next to each other, even in close installation, without heating each other up. This is ideal, for example, for textile machines, plastic machines as well as forming and bending machines

Additional Product Highlights

Optimized Three-Phase Current Asynchronous Motors: Baumüller will be presenting the optimized series of three-phase current, asynchronous motors DA1-100-280 at the trade fair. The company is thus continuing the modular strategy for the main drive, thereby continuing to merge the DA1 series with the series of synchronous motors DS2. Among other things, an optimized water cooling in the sizes 100/132/160, similar to the DS2-100-160, IE3 fan motors according to the new IE directives for the air cooled motors as well as an optimized connection technology are new with the three phase current asynchronous motor.

Flexible Multi-Axis Controller b maXX 5800: At the Hannover Messe, Baumüller will be exhibiting the flexible and compact multi-axis controller b maXX 5800. The controller for up to six drive axes can be configured individually and flexibly. This means that users can combine axis powers in the controller specifically to the application. The user can thus integrate exactly the right axis performance for each individual axis, resulting in a device that meets exactly the requirements of the user’sapplication

.

High-Performance Compact Drive b maXX 2500: The high-performance compact drive b maXX2500 with integrated electronics can be used regardless of the industry and therefore for numerous industrial applications, such as for robotics and handling applications. The decentralized servo drive reduces the wiring and installation costs, allows an optimal installation space, offers a high level of flexibility and is available in three sizes.

Press release from Baumueller