The DMG MORI Aerospace Excellence Center designs and implements pioneering process solutions for the most demanding applications in the aerospace industry.

Technology Excellence for the aerospace industry

The DMG MORI Technology Excellence Centers operate as central industry units for the leading industries of aerospace, automotive, die & mold and medical in the global sales network of the machine tool manufacturer. The global aerospace industry expands continuously by about seven percent per annum. The high quality demand and the tremendous amount of competitive pressure compels manufacturers and machinery suppliers to implement increasingly productive manufacturing solutions for the valuable and often safety-related aerospace components. This task is taken care of by the Aerospace Excellence Center in the DMG MORI plant in Pfronten.

Gear housing of a helicopter

With its 20 plus years of technology experience, the DMG MORI Aerospace Excellence Center is involved in all phases of customer and order acquisition. The service that are provided range from the optimization of existing metal cutting processes to the planning of so-called Green Field projects from scratch. “We also help customers to gain a foothold in the aerospace industry by means of industry-internal know-how for the manufacture of specific components”, adds Michael Kirbach, manager of the DMG MORI Aerospace Excellence Center. The range of services includes giving advice and also delivering holistic solutions within the scope of turnkey projects, including complete automation and many special options.

As Michael Kirbach is aware: “Demanding materials such as titanium alloys, powder-metallurgically manufactured high-temperature materials and ceramic compound materials will reveal the boundaries of metal cutting capability in the future”. Automation, digitization and holistic thinking about the respective process chains are therefore regarded as decisive production trends in the aerospace industry. “As far as automation is concerned, as well as the actual handling itself, the focus is also on the individual process in order to give the entire value creation chain a more reliable and reproducible structure.” As an example he mentions the Green Button process, i.e. a safe and reliable process which avoids manual intervention using automatic monitoring and control.

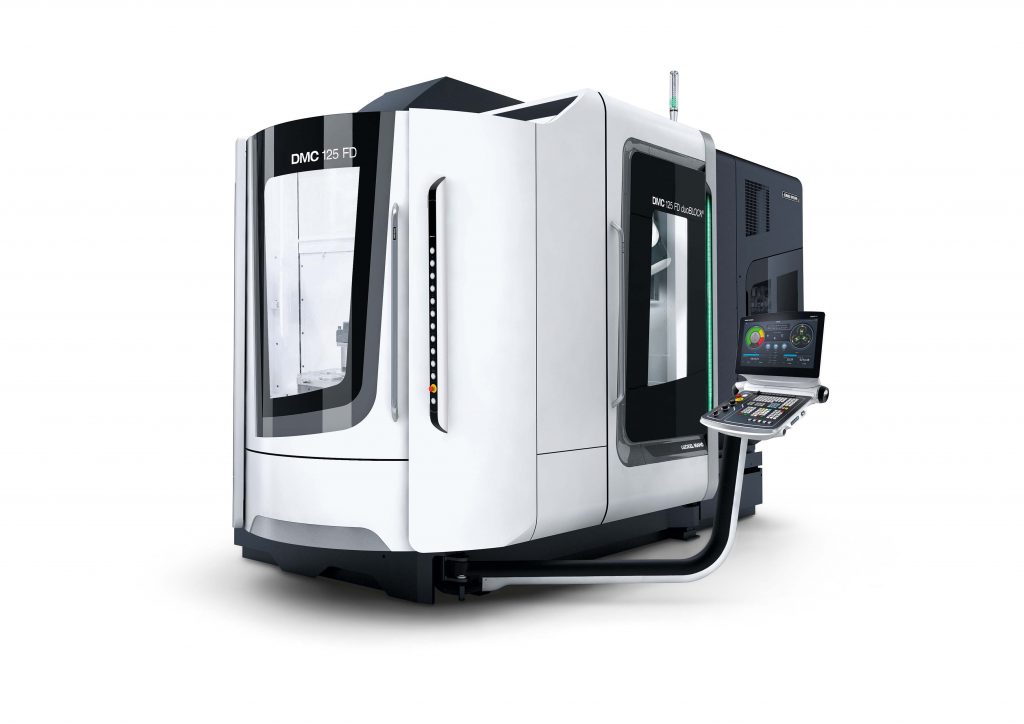

Michael Kirbach thinks that process optimizations such as this are vital: “The quantities and the high-quality components of today justify this effort more than ever before.” Digitization is said to be an important element in this respect, e.g. by using DMG MORI technology cycles such as the CONDITION ANALYZER. This is integrated in the CELOS app-based control and operating system “More and more aerospace component manufacturers are taking the opportunities provided by digitalization to analyze processes in a better way, understand them and optimize them – even control them adaptively if necessary.” At the EMO in Hanover, DMG MORI is demonstrating the easycenterSET innovative DMG MORI technology cycle on a DMC 125 FD, among other things. This is an automatically adjustable plate between the palette and the component device which measures the eccentricity of the pre-centered component and automatically centers it with accuracy of 5 µm. The documented result provides the customer with a high degree of process reliability during milling/cutting, particularly when using automation solutions.

Press release from DMG MORI