During Fakuma 2021, SIGMA Engineering presents the latest release of SIGMASOFT® Virtual Molding. It furthermore contains refined prediction of warpage besides numerous enhancements for calculation of multicomponent parts and introduces the new option to analyze compression molding processes.

Aachen, August 24th, 2021 – At Fakuma (12.-16. October 2021) in Friedrichshafen, Germany, SIGMA Engineering GmbH presents advancement of SIGMASOFT® on Booth A5-5110. The new and bigger exhibition space allows visitors to collect all details of the new Version 5.3.1 besides new application examples and simulation approaches.

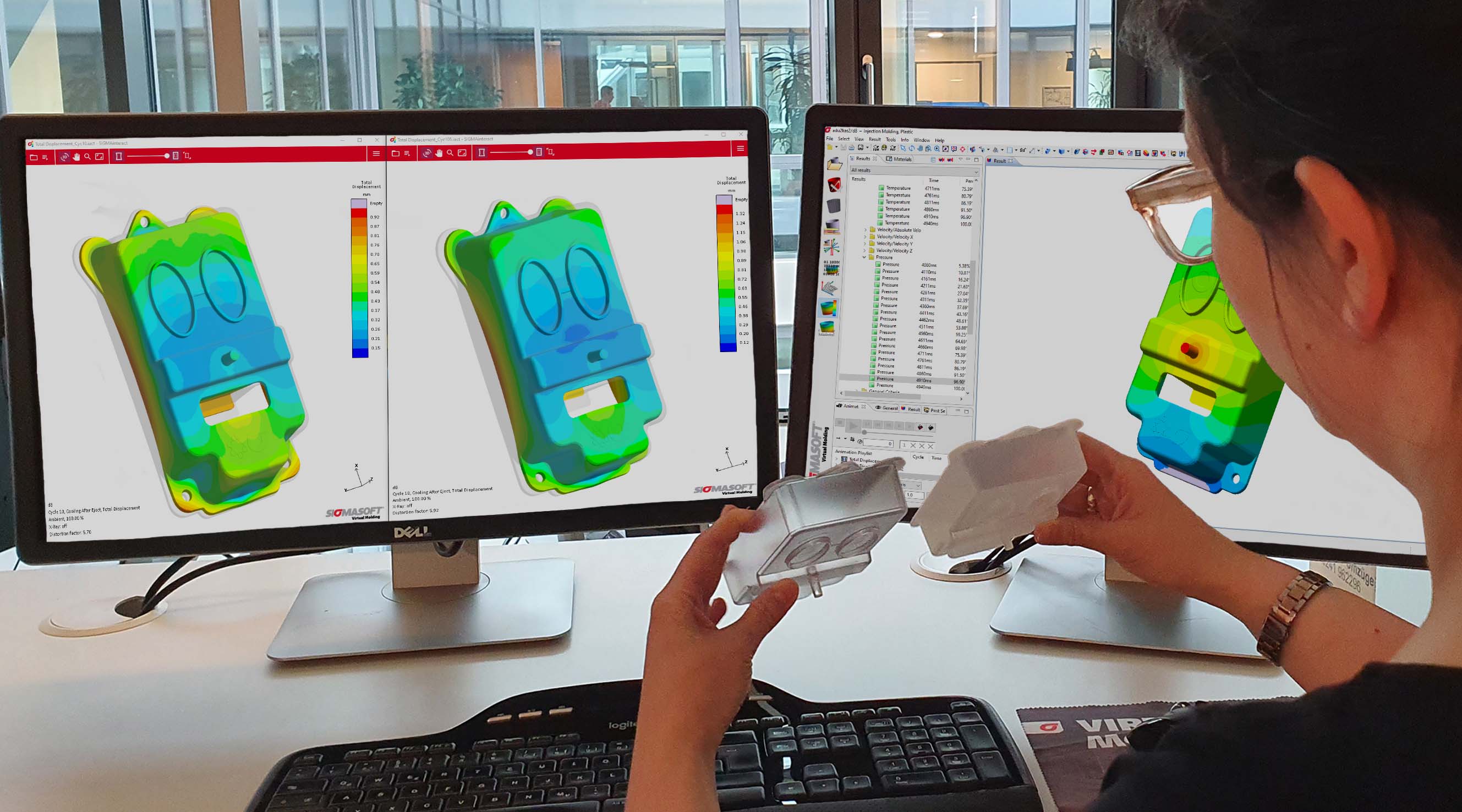

„We look forward to finally meeting our network of partners and customers in person again. The bigger space is a great support to showcase the benefits of our SIGMASOFT® Virtual Molding Technology and Autonomous Optimization. And we are happy to present the updates of the newest version in detail“, says SIGMA CTO Timo Gebauer. The update not only contains the new possibility to simulate compression molding processes of elastomers; it also offers many enhancements and improvements in the area of thermoplastics.

The prediction of warpage was again improved. „Since shrinkage and distortion are essential for the correct design of plastic parts, we continuously strive to compute them even more precisely“, Gebauer explains, „for example we are working with DUFNER.MDT GmbH since three years, to further improve our material datasets especially for warpage prediction.“ Besides the improved material data SIGMASOFT® v5.3.1 also contains new criteria, to make the evaluation more precise and user-friendly.

Another important update is introduced for the calculation of multicomponent projects. It is now possible, to run virtual Design of Experiments (DoE) and optimizations for all components at the same time, in order to adjust them precisely to each other. How to develop multicomponent parts including molds and process with the help of Virtual Molding and virtual DoE is also demonstrated at the SIGMA booth. The showcased example is the cell-phone-holder „Butterfly“ by Elmet, shown in full production on K show 2019.

Other recent practical examples created with support of SIGMASOFT® are shown on the fairground:

For 23 years, SIGMA Engineering GmbH has been driving the development of the injection molding process with its simulation solution SIGMASOFT® Virtual Molding. This virtual injection molding machine enables the optimization and development of plastic components and molds as well as the mapping of the entire production process. The SIGMASOFT® Virtual Molding technology combines the parts 3D geometries with its tooling and temperature control system and integrates the parameters of the production process. This ensures a cost-efficient and resource-saving production as well as high-performance products – from the first shot.

SIGMASOFT® Virtual Molding integrates a multitude of process-specific models including 3D simulation technologies that have been developed and validated over decades and are continuously optimized. The SIGMA Solution Service and Development team supports its customers technical goals with application-specific solutions. The software company SIGMA offers application engineering, training, direct software sales and as a result, a software straight from its developers and designers to help give a solution service by engineers all over Europe.

SIGMA Engineering GmbH, headed by Managing Director Thomas Klein, has subsidiaries in the USA, Brazil, Singapore, China, India, Korea and Turkey. In addition, SIGMA supports its users worldwide in a variety of international companies and research institutions with its Virtual Molding technology.

Weitere Infos: sigmasoft.de