Optimally designing a family mold employing virtual DoE

The design of family molds poses specific challenges for injection molders as well as mold makers. Usually, a balanced filling of the different cavities can just be achieved by means of a well-considered runner system. The virtual DoE, included in the SIGMASOFT® Autonomous Optimization, helps users finding the ideal runner concept for molds with very different cavities with just one calculation.

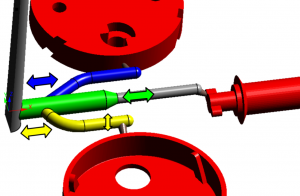

Figure 1 – Four degrees of freedom for geometry changes are defined for the first virtual DoE: The starting points of the lateral sprues (blue & yellow), the diameter of the bottom sprue (yellow) and the local increase of thickness at the main sprue (green)

Balancing the Mold via Geometry Optimization

Aachen, October 16th, 2018 – At Fakuma, SIGMA Engineering GmbH from Aachen showcases the newest applications of its SIGMASOFT® Autonomous Optimization, exhibiting at booth A5-5105. In this new simulation approach, now contained in the SIGMASOFT® Virtual Molding technology, the user defines a specific objective, e.g. the balanced filling of multiple cavities, and the simulation determines the configuration optimally fulfilling this objective, using just one calculation with a variety of variables. The user compares different configurations based on specific values, significantly shortening the time to find the best result. Consequently, trial-and-error experiments are not just moved from the injection molding machine to the computer but reduced to a minimum, since the software facilitates the user’s decisions regarding geometry or process changes.

In the example at hand, the runner system of a family mold should get optimized to achieve a balanced filling of the different parts. These are differing considerably in volume and wall thickness. Therefore, filling happened to be very unbalanced with the original runner system, leading to a single component affecting the productivity of the entire process.

The possibility to execute a virtual DoE (Design of Experiments) is an integral part of the Autonomous Optimization. It was utilized to optimize the design and achieve a balanced filling of all cavities of the aforementioned family mold. Initially, the adjustable geometric parameters were determined (Figure 1). The length of the main sprue’s local increase of thickness, radius of the bottom sprue and the respective starting points of the lateral sprues, where they branch away from the main sprue were specified as degrees of freedom. Additionally, the desired target value was defined. These are minimal differences in filling times of the individual components as well as a low filling pressure.

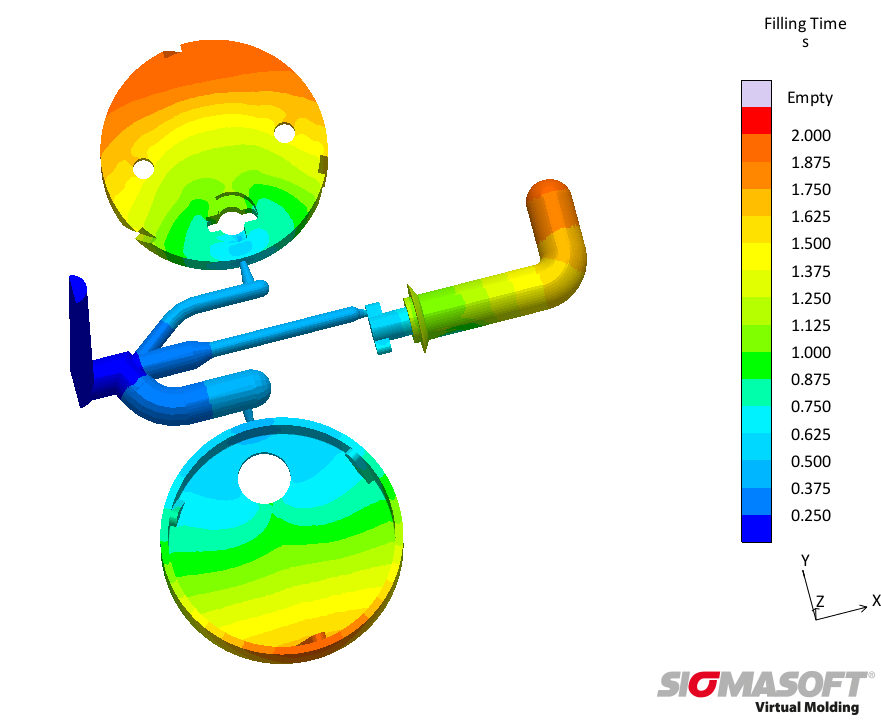

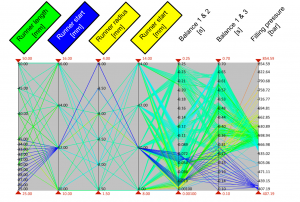

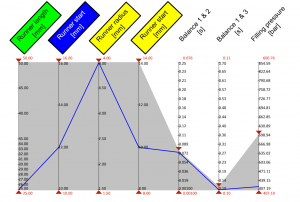

After calculating all geometry variants with the help of a virtual DoE, they are compared and evaluated regarding the differences in filling times (Figure 2). On the left side, all calculated variants are shown each represented by a colored line. The specific columns are depicting the degrees of freedom and target values, as well as their possible characteristics. Afterwards, the user utilizes the sliders at the columns to limit the target values to the desired values, identifying the optimal variant (Figure 2, right). In this example, the filling pressure should be lower than 600 bar while the maximal difference in filling time for the cavities amounts to 0,1 s. The determined runner design shows a distinct increase in filling balance of the individual cavities (Figure 3). Subsequently, this geometry will be used as basis for more detailed optimizations of mold and process configuration.

By means of the virtual DoE, contained in the SIGMASOFT® Autonomous Optimization, geometrical changes can be checked with very slight effort. At the same time, the influence on defined objectives, e.g. differences in filling times of multiple cavities or filling pressure, can be evaluated. Hereby, users can find the ideal runner design to match their requirements very fast and safely, even while combining very diverse parts in their molds.

Figure 2 – In evaluation, every version is represented by one line, the vertical sliders show degrees of freedom and target values (left). The user can narrow both down via the sliders and thus identify the ideal variant (right)

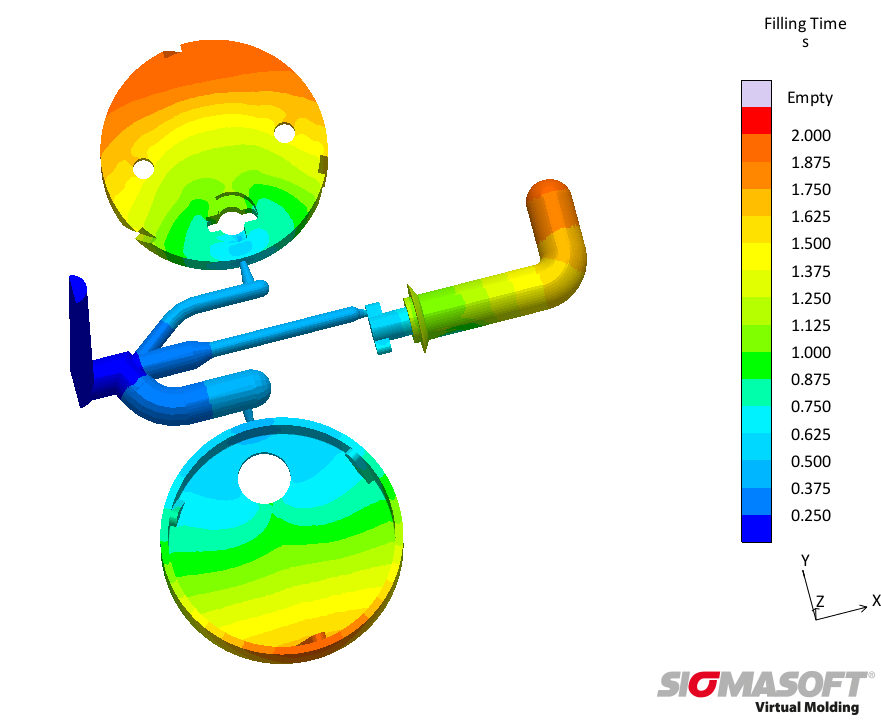

Figure 3 – Optimal design with balanced filling and approximately even filling times in all cavities

SIGMA (www.sigmasoft.de) is sister company to MAGMA (www.magmasoft.de), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® Virtual Molding technology optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® Virtual Molding combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA and MAGMA, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® Virtual Molding thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT® Virtual Molding provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® Virtual Molding provides this communication. SIGMA support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

Press release from Sigmasoft