Redeveloping a globally known product with a unique selling point requires a good team and a lot of patience. When the next optimization step is then accomplished, it is the best argument for the work that has been put in. From October last year, the new water flow controller series 110 and 310 from WITTMANN are available.

For more than 40 years, WITTMANN flow controllers have been part of the standard equipment for every injection molding machine. With more than 500,000 devices sold, they have long been the undisputed number 1.

The predecessor models 101 and 301 had satisfied users worldwide for decades. They were used for distributing cooling water and cooling molds as well as specific areas inside injection molding machines, such as the feed zone, or the oil cooling system in hydraulic machines. The new 110 and 310 flow controller series are setting new benchmarks to ensure the ongoing technical progress for these products, which seem simple at first glance but prove being sophisticated when taking a closer look.

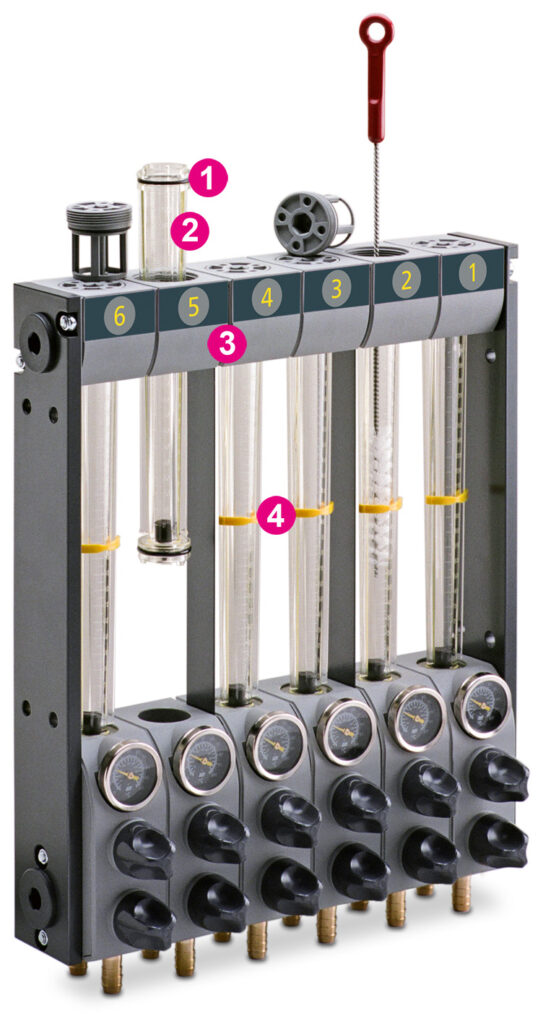

1: EPDM O-ring. – 2: Polyamide 12 is the best choice of material for use with hot water up to 100 °C. – 3: For the heavy-duty use, a fiber-glass-reinforced PPO (polypropylene oxide) compound has been chosen as the material for the top and bottom parts of the flow controller’s housing. – 4: Adjustment rings to display the flow quantity.

Proven and new features

The tried-and-tested method of pipe cleaning, which can be carried out without removing the pipe through the top part of the housing, has been left unchanged in the 110 and 310 series. It is easy to replace the O-ring by lifting the pipe out of the bracket and then pulling it through the housing.

An absolute novelty is the new control valve that allows precise control of the flow rate. The double sealing of the valve disk towards the spindle and the axial movement performed by the valve disk instead of a radial movement are also novelties in the sector of cooling water flow controllers. With these features, WITTMANN is setting a new, unprecedented standard!

These vital innovations contribute to reduced wear of the O-rings and extend their service life. The O-rings themselves are made of EPDM and offer a high level of chemical and thermal resistance. As before, the sensor tube of the thermometer is placed directly in the return water and thus responds very quickly to temperature fluctuations. To keep the pressure drop inside the flow controller to a minimum, the cross-sections have been designed as large as possible, since a minimal pressure drop constitutes a decisive advantage at low system pressure.

Interesting options

Additional valves are also offered for the new 110 and 310 series, such as the central shut-off or Z-valve for central blocking of the water supply to several circuits in the event of interruptions in the injection molding cycle. Single shut-off valves or E-valves are available as well, which are used to interrupt the cooling process in individual mold circuits by cutting off the cooling water flow. E-valves are normally used in combination with temperature sensors evaluated by the injection molding machine’s control system. In this way, temperature control of individual mold cooling circuits can be performed by cooling pulses.

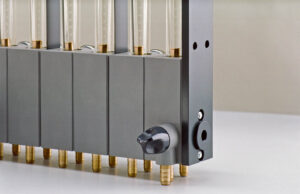

Solenoid shut-off valves (left) and optional blow-out valve.

The blow-out valve, which is also available as an option, has an additional compressed air connection and enables – usually in combination with the Z-valve – emptying of the mold circuits by blowing out the cooling water.

Specifications

Series 110

The essential device for your plastics processing machines for open and closed cooling circuits. Flow volume is indicated in accordance with the float measuring principle: a cone is lifted by the water flowing in the return of the mold circuit.

Series 310

The optimum flow regulator for large injection molding and blow molding machines. Its low pressure drop makes it suitable for highest flow volumes. However, by means of a special design of the regulating valves, excellent regulation and accurate reproduction of cooling water volume and temperature in the different mold circuits can also be achieved for low flow volumes.

Flow range per circuit:

Standard 0–30 l/min.

On request:

AI, PVC-cones.

Standard:

mold connections with G 3/8″ brass threaded sleeve.

Option:

with screwed 14 mm brass socket for 1/2″ hose, or screwed 20 mm brass socket for 3/4″ hose.

The WITTMANN Group

The WITTMANN Group is a globally leading manufacturer of injection molding machines, robots and auxiliary equipment for processing a great variety of plasticizable materials – both plastic and non-plastic. The group of companies has its headquarters in Vienna, Austria and consists of two main divisions: WITTMANN BATTENFELD and WITTMANN. Following the principles of environmental protection, conservation of resources and circular economy, the WITTMANN Group engages in state-of-the-art process technology for maximum energy efficiency in injection molding, and in processing standard materials and materials with a high content of recyclates and renewable raw materials. The products of the WITTMANN Group are designed for horizontal and vertical integration into a Smart Factory and can be interlinked to form an intelligent production cell.

The companies of the group jointly operate eight production plants in five countries, and the additional sales companies at their 34 different locations are present in all major industrial markets around the world.

WITTMANN BATTENFELD pursues the continued strengthening of its market position as a manufacturer of injection molding machines and supplier of comprehensive modern machine technology in modular design. The product range of WITTMANN includes robots and automation systems, material handling systems, dryers, gravimetric and volumetric blenders, granulators, temperature controllers and chillers. The combination of the individual areas under the umbrella of the WITTMANN Group enables perfect integration – to the advantage of injection molding processors with an increasing demand for seamless interlocking of processing machines, automation and auxiliaries.

More informations at Fortuna.gr