Upfront simulation of the core pins’ deformation helps choose the mold materials

SIGMASOFT® provides a variety of methods to forecast the shrinkage and warpage of plastic parts. Along with this, one can also simulate the deformation of inserts or core pins during filling. SIGMA simulates and compares the deformation of core pins made of two different mold materials under equal process conditions. The calculations are based on the imbalanced melt flow inside the cavity and the mechanical properties of the two materials.

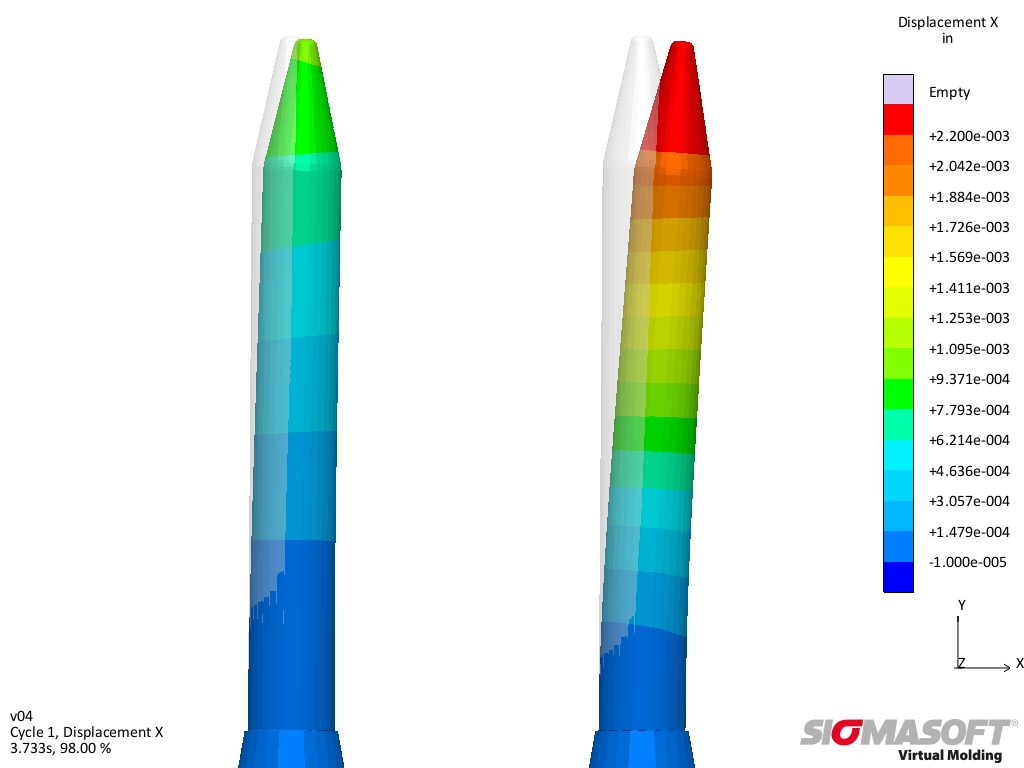

Figure 1 – Simulative comparison of the deformation of core pins made of tungsten carbide (left) and 420 stainless steel (right) at the end of the filling of the cavity – the material with the lower modulus of elasticity deforms three times more under constant process conditions.

Easier Decisions in Mold Design Using Virtual Molding

Aachen, October 10th, 2019 – There are many questions that injection mold manufacturers confront daily regarding the variety of mold materials which are available in the market. What type of steel should be used for which part of the mold? Whether it is the thermal conductivity of the steel used for the cavity insert, the diameter of a suitable ejector pin or even the mechanical stability of the core pins, SIGMASOFT® Virtual Molding leads to the correct decision.

In SIGMASOFT® every mold material, e.g. steel, isolation, etc., is taken into account with its thermal and mechanical properties. As an example, one can simulate the heating up phase or the developement of hotspots during several injection cycles having the thermal conductivity and specific heat capacity of all the mold materials. Besides the prediction of shrinkage and warpage of plastic parts, SIGMASOFT® also simulates the deformation of inserts and core pins during filling. These calculations are based on possible imbalances in the filling of the cavity and of course the mechanical properties of the steel.

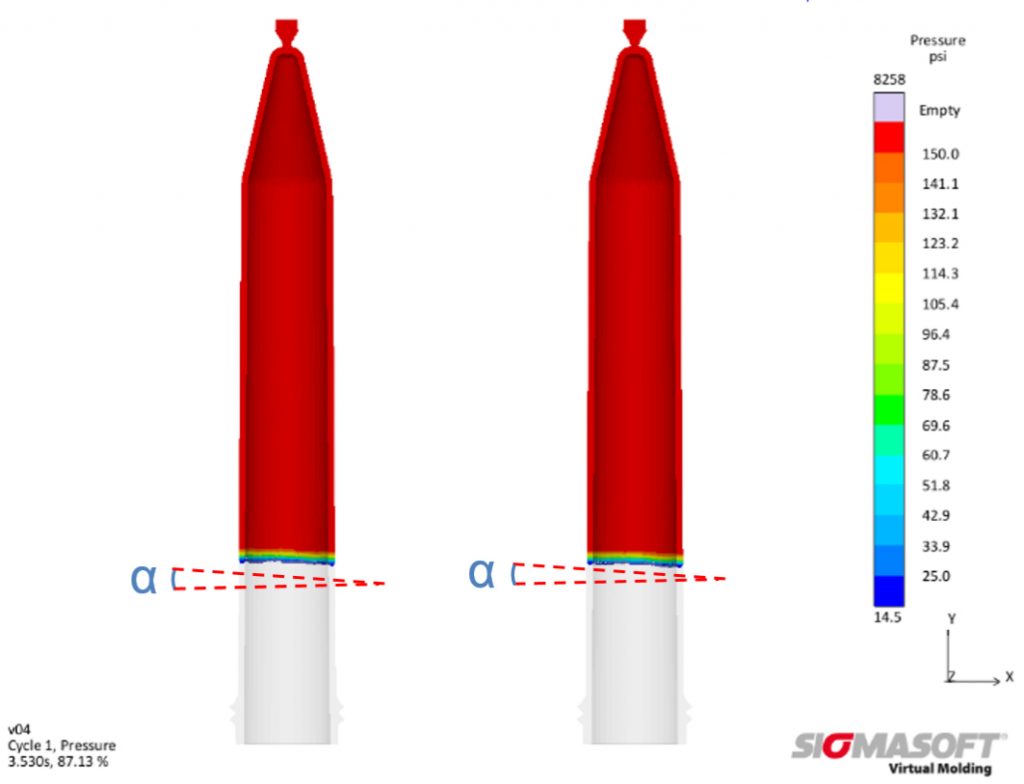

SIGMA Plastic Services, Inc. (IL), the American subsidiary of SIGMA Engineering GmbH, simulated an interesting project in cooperation with two companies, CAVAFORM (FL) and Crafts Technology (IL). In the project the deformation of core pins made of different materials during filling of the cavity was evaluated. The investigation was done for an injection mold with 16 cavities, which is used to produce centrifuge tubes. In 8 of these cavities, core pins made of tungsten carbide are integrated to form the inside of the tubes. 420 stainless steel is used for the other 8 core pins. Simulative analysis of the filling phase shows an imbalance, which comes to existence after about 85% of filling has passed and becomes more obvious near the end of filling (Figure 2). This imbalance is caused by the asymmetrical geometry of the screw in the cap area of the tube and leads to a force, which tends to deform the core pins during the filling of the cavity. Due to the lower module of elasticity of 420 stainless steel, pins made of this steel are deformed about 3 times more compared to the pins made of tungsten carbide (Figure 1).

The described case is just an example of the many details of an injection mold, which can get misplanned during the mold design phase. SIGMASOFT® Virtual Molding provides even the most experienced mold manufacturers with a detailed insight of the injection molding process. With a very low effort and based only on the thermophysical and mechanical phenomena, even before ordering the mold units, they can examine and evaluate the effect of changes in the mold. Thus, simulation provides a sound basis for decisions and supports the mold design from the beginning.

Figure 2 – Demonstration of the melt pressure in two cavities with core pins made of tungsten carbide (left) and 420 stainless steel (right) – The upper section shows the point in filling where the imbalance is visible for the first time. At the end of filling (lower section) this phenomena can be seen clearly.

SIGMA (www.sigmasoft.de) is sister company to MAGMA (www.magmasoft.de), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® Virtual Molding technology optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® Virtual Molding combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA and MAGMA, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® Virtual Molding thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 30 years. A process-driven simulation tool, SIGMASOFT® Virtual Molding provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® Virtual Molding provides this communication. SIGMA support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.