Renishaw, a world leader in precision engineering technologies, will be exhibiting its extensive range of metrology and additive manufacturing systems on two stands at EMO Hannover 2017 which takes place in Germany from 18 – 23 September 2017. Intelligent machining processes are critical to companies that want to exploit the full benefits of Industry 4.0 and throughout its main stand (hall 6, B46) Renishaw will demonstrate the power of integrating its latest measurement technologies within a manufacturing process.

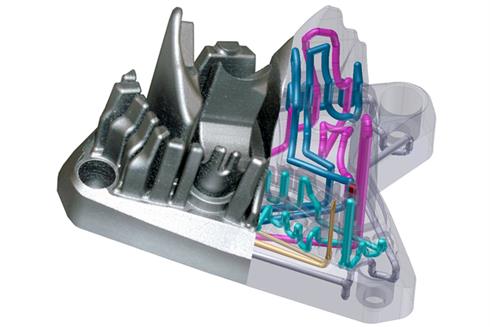

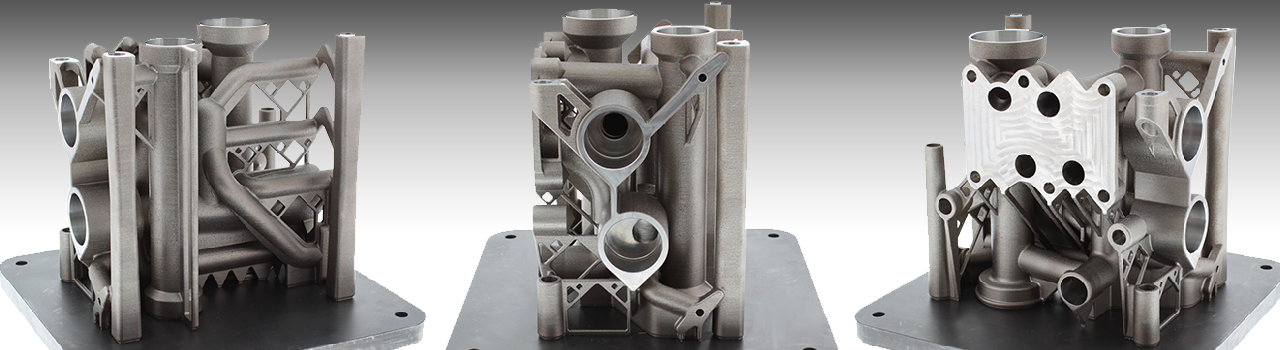

In hall 27, Renishaw will also exhibit in the new Additive Manufacturing Zone, where it will demonstrate software and systems for metal part manufacture at stand A72. This includes the latest version of the company’s build file preparation software, QuantAM 2017, which has been designed specifically for Renishaw metal additive manufacturing systems; RenAM 500M and AM 400.

Products highlighted in hall 6 will include a new contact scanning system for CNC machine tools, new software for the Equator™ flexible gauge which allows users to fully integrate the system with CNC machine tools, new on-machine and mobile apps that simplify the use of machine tool probing, an enhanced non-contact tool setter for machining centres, a new multi-probe optical interface system, a new surface finish probe for co-ordinate measuring machines (CMMs), and new software that enhances the functionality of Renishaw’s XM-60 multi-axis calibration system.

A new machining cell concept with integrated process control will also be shown, demonstrating how complementary technologies can contribute to high levels of productivity and manufacturing capability.

At EMO Hannover 2017, Renishaw will demonstrate a new member of its award-winning SPRINT product family for on-machine scanning. The new SPRINT system with SupaScan is designed for simple integration into machine tool applications requiring exceptionally fast workpiece set-up, and where overall cycle time is critical, bringing the benefits of scanning technology to the mass market. The system also provides the ability to perform advanced scanning functionality such as monitoring the final condition of a component surface.

SupaScan technology delivers workpiece set-up cycles which measure accurately even at rapid feedrates (G0), resulting in the fastest possible spindle probe-based solution for workpiece set-up. Testing on typical industrial components has seen cycle time reductions of over 70% when compared to standard high-speed touch-trigger cycles.

The Renishaw Equator™ flexible gauge is now offered with IPC (intelligent process control) software, providing the functionality to fully automate tool offset updates in CNC manufacturing processes. Improved capability in precision part machining, reduced setting and process adjustment time, and integration with automation systems are some of the benefits that users can now expect.

The new IPC software allows constant monitoring and adjustment of a machining operation, keeping part dimensions close to nominal and well within process control limits. This means that any process drift is quickly corrected, improving part quality and manufacturing capability, along with reducing scrap. The proximity of the Equator gauge to the CNC process allows rapid measurement and process adjustment at the point of manufacture, avoiding time delays or relying on finished part (tailgate) inspection.

The increasing frequency with which machine tool builders are integrating Microsoft® Windows®-based touch-screens into machine tool controls provides an ideal platform for the development of on-machine apps which support machine tool probing functionality. Renishaw has a newly augmented suite of on-machine apps which allow probe routines to be swiftly and simply created, executed and reviewed, helping manufacturing organisations to minimise cycle times and maximise productivity.

The Set and Inspect app, supporting probe calibration, part setting, tool setting and component inspection, is so simple that virtually no training is required: just select the required probing cycle from its icon-driven programming environment and then complete the necessary input fields. Reporting is a complementary, real-time process monitoring app. Generating highly-visual, graphical representations of measurement data and displaying the pass, fail or warning status of each measurement, the app is an ideal tool for basic trend reporting.

Renishaw will also demonstrate its developing range of smartphone apps for machine tool probes and tool setters. GoProbe is an enabling technology embedded within the latest Renishaw macro-based software packages. Together with associated training materials and user reference tools, this technology is designed to make using Renishaw machine tool probes and tool setters simple.

Renishaw machine tool probes are supplied with several customisable settings allowing them to be configured for a specific application. This customisation technique is known as Trigger Logic™. The Trigger Logic app provides users with a simplified method of customising their Renishaw probe settings that is faster and easier than following traditional printed instructions. A series of integrated illustrations and videos clearly explains the configuration process where more information is required.

Renishaw will also introduce its enhanced and extended NC4+ non-contact tool setting solution for machining centres. Building on the highly successful and proven design of the existing NC4 system, this enhanced solution introduces a range of additional features and options to satisfy the demands of the rapidly evolving manufacturing environment.

Comprising the NC4+ non-contact tool setter and NCi-6 interface, the system provides a high-speed, high-precision solution to determine tool geometry, check tool condition and track thermal changes on a range of 3-axis and 5-axis machining centres.

A new multi-probe optical interface system for machine tool probe systems will also be introduced at EMO Hannover 2017. Expanding on the highly successful OSI/OMM-2 optical probe interface system, the introduction of the new spindle-mounted OMM-2C receiver provides a compact and convenient solution allowing installation of up to three Renishaw machine tool touch probes with optical signal transmission communicating via a single interface.

System design ensures robust operation whatever the operating environment. Utilisation of Renishaw’s ‘modulated’ optical transmission technology offers unparalleled resistance to light interference, whilst an optional, integrated air blast ensures the receiver window remains clean and debris-free for uninterrupted system communications.

EMO Hannover 2017 also sees the launch of a new, improved surface finish measurement probe for use with Renishaw’s REVO® 5-axis measurement system on CMMs. The new SFP2 probe allows users of the multi-sensor REVO system to fully integrate surface finish measurement and dimensional inspection on a single CMM, giving unrivalled advantages over traditional methods requiring a separate process.

The SFP2 system consists of a probe and a range of modules and is automatically interchangeable with all other probe options available for REVO – touch-trigger, high-speed tactile scanning and non-contact vision measurement. Data from multiple sensors is automatically referenced to a common datum.

Building on the launch of the Renishaw XM-60 multi-axis calibrator in September 2016, the new release of CARTO 2.1 software brings valuable new functionality. The new ‘free-run mode’ allows users of the XM-60 calibration system to capture data immediately, without having to define the positions, or even the number of targets. The software displays straightness (horizontal and vertical), pitch, yaw and roll errors against linear position. Triggering can be manual (with a keypress), automatic (based on stability of position) or continuous (captured during motion at a user-defined interval).

Visitors to EMO Hannover 2017 will also see Renishaw’s new machining cell concept which demonstrates how the ability to monitor key process inputs, analyse data and continuously improve manufacturing processes facilitates increased productivity and higher accuracy. Simply measuring the output of a manufacturing process using ‘tailgate’ inspection is not enough and, more often, too late to control all the variability in a manufacturing process. It is critical that checks and measurements are also made before, during and immediately after machining to control both common-cause and special-cause variation.

For further information on products being shown at EMO, visit www.renishaw.com/emohub

Press release from Renishaw