Accompanying the development process with SIGMASOFT®, from part design, over mold design to production

At this year’s K Show SIGMA Engineering aligns its booth concept with the motto “SIGMAinteract – Autonomous Optimization connects departments” and presents its new SIGMAinteract. In a cooperation project SIGMA shows how to use virtual DoE during the entire development process of the project. With SIGMAinteract results are displayed interactively and in 3D. Thus, its usage makes knowledge tangible and easy to share between departments.

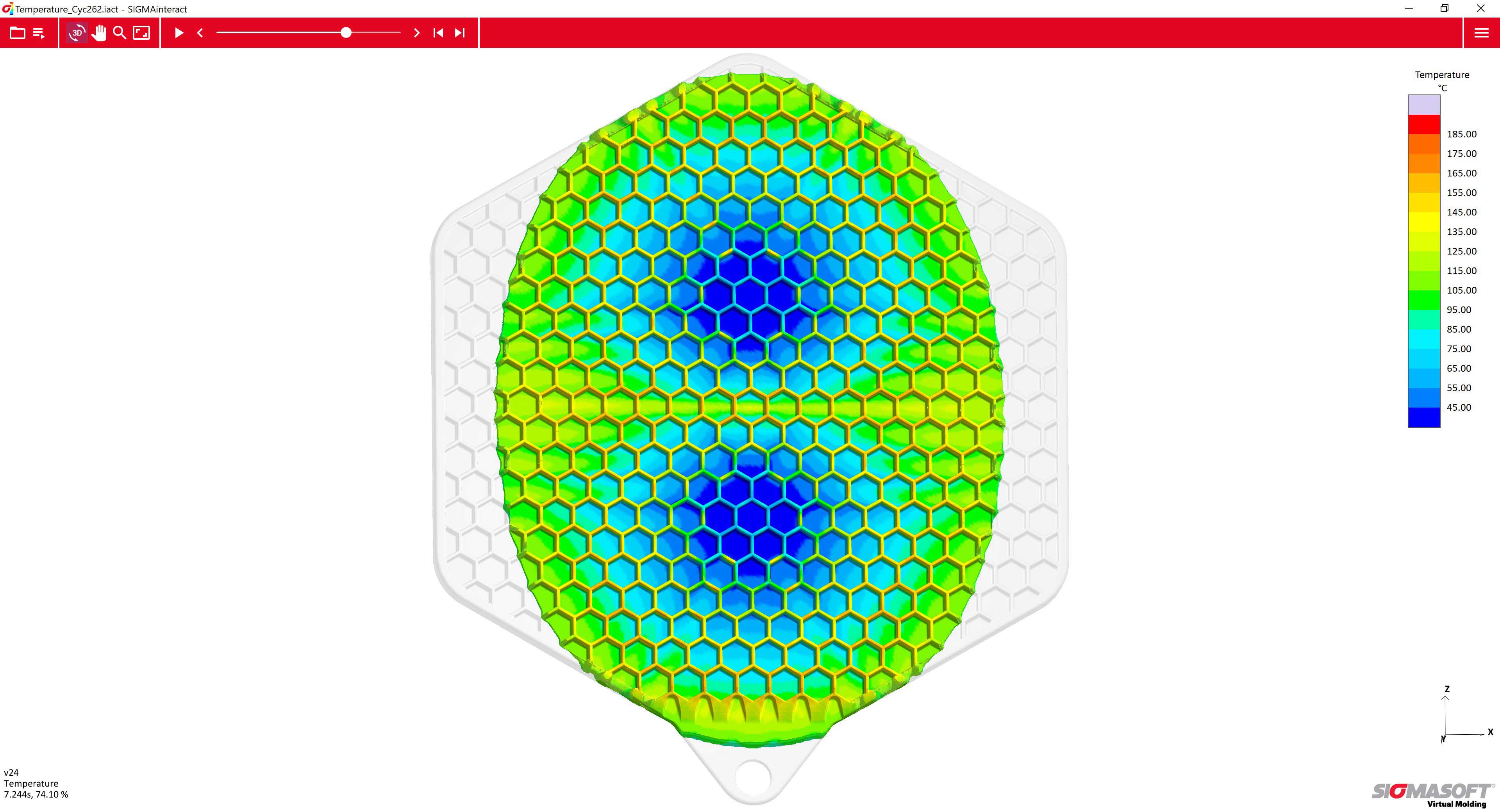

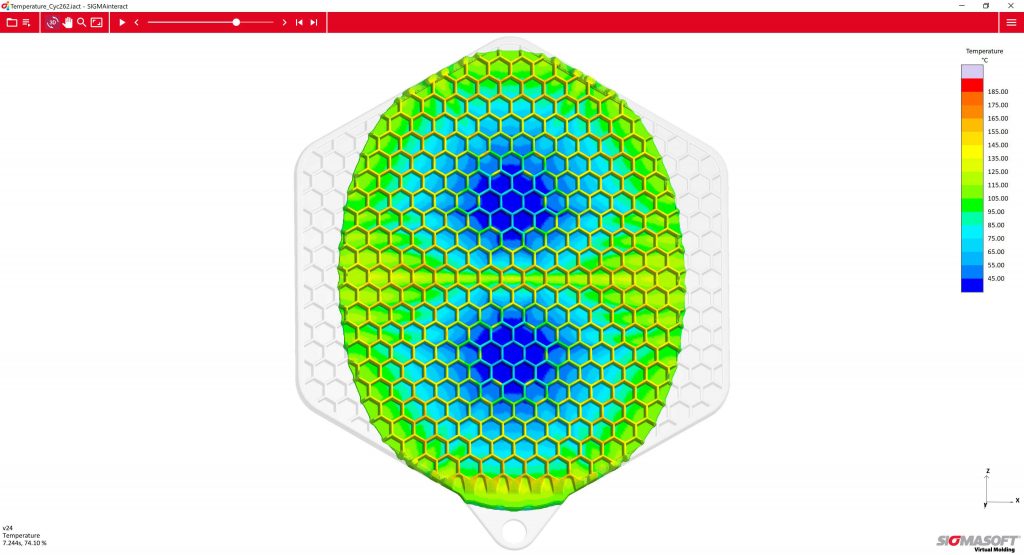

Figure 1 – SIGMAinteract: Temperature distribution in the part during filling, shown on an interactive 3D model, here at 74% filled.

Utilizing Virtual DoE over the Entire Development Process

Aachen, July 31st, 2019 – For SIGMA Engineering GmbH the K 2019 (16th – 23rd October 2019, Düsseldorf, Germany) is all about “SIGMAinteract – Autonomous Optimization connects departments”. At the SIGMA booth in hall 13 at booth B31 this immediately becomes visible with a completely new design concept.

Making informed decisions throughout a project requires involvement from partners in various departments. This means project data must be provided to each participant and they will need free and easy access to it. Therefore, SIGMA presents its new SIGMAinteract: Now, users can share SIGMASOFT® results interactively and in 3D with colleagues, project partners and customers. SIGMASOFT® hereby encourages the interdisciplinary exchange and provides a direct link between the simulation in development and production.

Visitors can experience and use SIGMAinteract live at the booth. There, SIGMA will demonstrate how virtual DoE is used most efficiently and how the SIGMAinteract tool significantly contributes to a good interdisciplinary exchange. As a demonstration SIGMA uses the project “Pot Cloth”, which was realized as a collaborative project with Momentive Performance Materials GmbH, Germany, EMDE MouldTec GmbH, Germany, Wittmann Battenfeld GmbH, Austria, and Nexus Elastomer Systems GmbH, Austria.

In this project part design and tool construction were done in parallel. Therefore, it was necessary for all partners to work closely together. Simultaneously, SIGMA conducted a virtual DoE for the validation of the part design and the evaluation of the heating concept.

The SIGMASOFT® results showed that the honeycomb structure of the part placed high requirements on the material and the tool. There was also a high possibility for air entrapments at the weldlines of the comb walls and premature curing during filling which would need to be prevented. The hanger was what determined the cycle time. With help from SIGMASOFT® the ideal length and power of the heating cartridges was determined to achieve an even temperature distribution in the cavity area.

Combining the results of these two DoEs, a common ground for all project partners was created and the project board could make fast and well-founded decisions: A venting system was implemented into the tool. Premature curing was prevented via a well-chosen material and the part could also be scaled up. The hanger was redesigned allowing the heating time to be reduced by five seconds.

At the SIGMA booth visitors can observe the production of the “Pot Cloth” virtual and live. It will be produced on a SmartPower 90/350, control UNILOG B8, from Wittmann Battenfeld [booth 15C06]. The LSR injection molding tool including the cold runner system was constructed by EMDE MouldTec [booth 12A21]. The system is completed by a ServoMix X200 dosing system from Nexus Elastomer Systems [booth 12E49-01]. Silopren LSR 2640 from Momentive Performance Materials [booth 6B15] is used as material for the production.

As an example, for the knowledge transfer during the product and tool design phase central results are directly presented interactive and in 3D on the machine with SIGMAinteract. Thereby, simulation and production are directly linked together. The visitors see in a descriptive manner, how to share simulation results with colleagues and customers quickly and easily.

SIGMA (www.sigmasoft.de) is sister company to MAGMA (www.magmasoft.de), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® Virtual Molding technology optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® Virtual Molding combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA and MAGMA, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® Virtual Molding thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 30 years. A process-driven simulation tool, SIGMASOFT® Virtual Molding provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® Virtual Molding provides this communication. SIGMA support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

Press release from SIGMA Engineering GmbH