Where planing takes place, splinters and, where punching takes place, punching waste and good parts are falling. Strack Norma, one of the leading standard part suppliers in Europe offers a part conveyor for the removal. It is robust, flexible and space saving and thus offering an alternative to traditional conveyor belts.

Removing sharp-edged punching- and bending waste safely and efficiently often poses a major challenge.

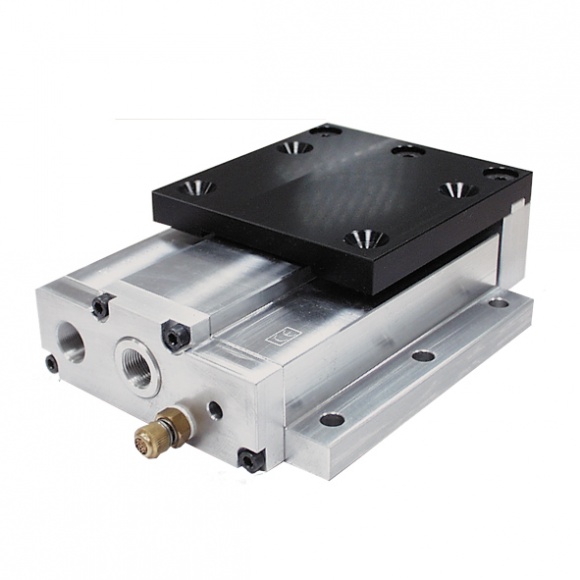

The conveyor belts, frequently used up to now, can wear easily. The pneumatic part conveyor of Strack Norma, a linear conveyor that removes punching parts of all kinds and shapes also out of extremely tight waste shafts, offers a solution here. It removes the parts on a sheet groove and is therefore particularly resistant to sharp and pointed metal parts. At the same time, it has a space-saving low design, but can also transport good parts and waste safely over an inclination of up to eight degree (8°) without falling down. Also oiled punching parts can be removed thanks to the structured transport sheet.

The robust and low-maintenance part conveyors can optionally be mounted or dismounted at any press and can thus be exchanged among each other. As a result, the operator can use them exactly where they are needed. This increases flexibility. Unused spaces can become accessible and free scopes can be created. All components are available as spare parts which guarantees a high and long-lasting overall application performance.

The linear conveyors operate according to the principle of speed- and surface friction relation. The easy handling of the device allows a quick and trouble-free operation.

Its transport speed can be individually adjusted via the stroke frequency- between 10 and 180 strokes per minute and can be adapted to the conditions on site. It works with a noise level of up to a maximum 70 dB(A). It is designed for a pressure of 3,9 up to 4,7 bar and available in four types.

In order to easily remove the transport groove in the tool in case of malfunctions or maintenance works, STRACK NORMA has developed a variable module for supporting the groove. It is used for the proper guidance and bearing of the groove and can be fixed from the outside. SN9810 is adaptable in length and width to the local conditions and facilitates the handling for the tool setter.

Source: fortuna.gr