Schwaig, October 16, 2019 – At K-2019, Sumitomo (SHI) Demag Plastics Machinery GmbH in collaboration with LSR specialist Nexus is showcasing a full turnkey LSR exhibit, moulding high-end light guides for automotive LED matrix headlights.

To mark the launch of the company’s brand new ready-to-use precision IntElect LSR injection moulding package, Sumitomo (SHI) Demag is producing probably one of the most challenging top-end LSR application on the market today – a matrix headlight delivering adaptive optic distribution for road vehicles. “If a company can injection mould a high-spec LSR component like this, any engineering, lighting, electrical or medical LSR application is feasible,” exclaims Thomas Kottler, Project Manager for LSR at Sumitomo (SHI) Demag.

By selecting equipment partners that are entirely dedicated to LSR, Sumitomo (SHI) Demag is sending out a strong message to the market. In creating a fully operational and automated start-to-end LSR moulding cell that doesn’t compromise on any performance aspect, the company and its select partners are setting a new benchmark for precision, part quality and production efficiency.

Best machine for the job

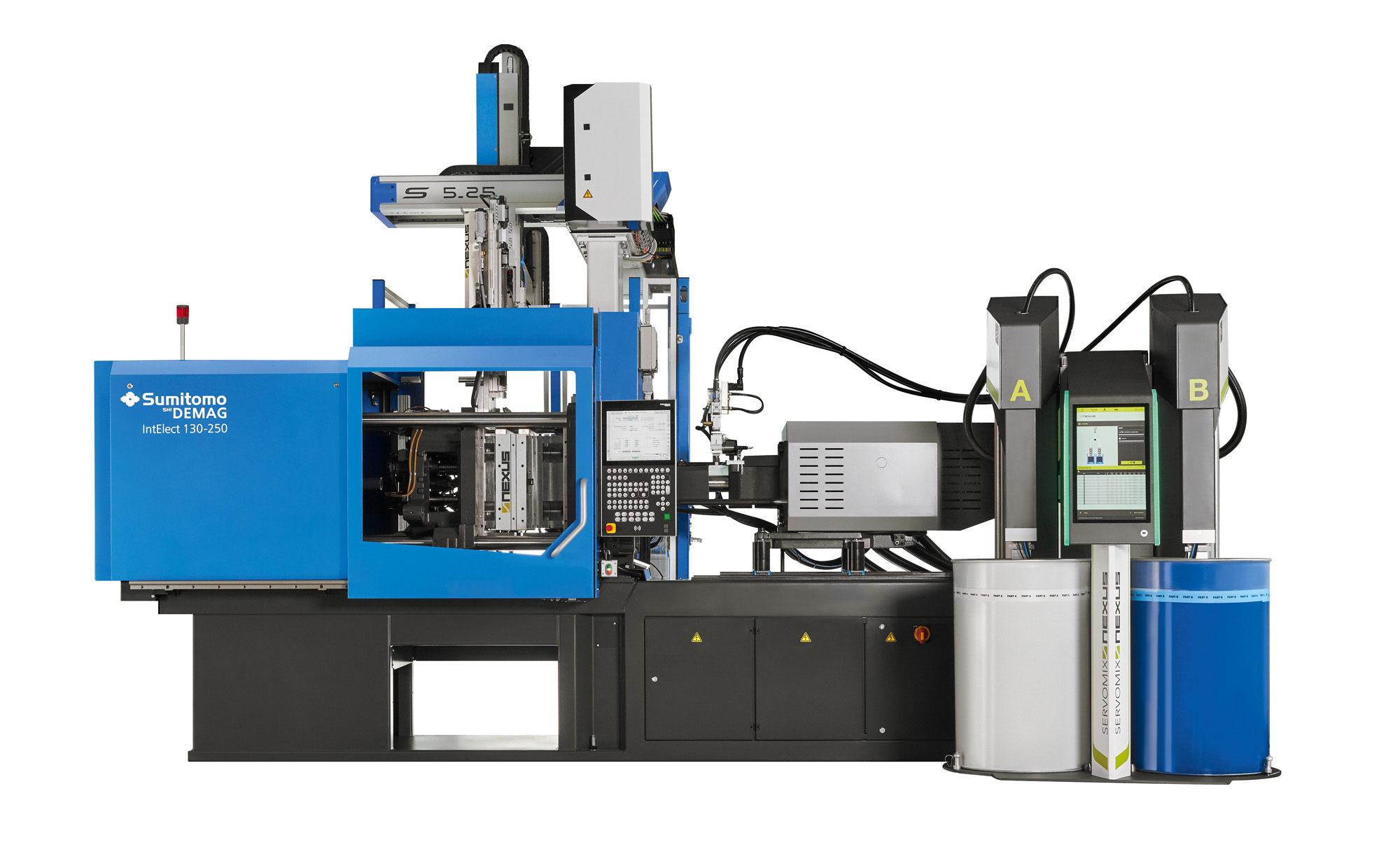

The injection moulding system on show at K-2019 is a specially configured all-electric IntElect 130 equipped with a special screw, non-return valve, vacuum system and other LSR-specific options. As the base unit, the IntElect range already stands apart from competitor LSR systems, and is especially proficient at handling challenging applications.

Notably, the IntElect’s drive system is geared towards top dynamics, precision and repeatability. Combined with the in-built mould safety system and 20% reduced energy consumption compared to competitor systems, the IntElect machine is integral to the processing stability, efficiency and availability required for handling an optical grade silicone material.

Thomas explains: “The low viscosity of the LSR material requires high precision processing. This is exactly what the IntElect direct drives are designed to deliver, ensuring exact positioning of the screw during the injection of material. Additionally, LSR acts in the opposite way to a thermoplastic material with regard to heat and consistency. As a result, the cylinder has to be cooled in order to avoid curing of the material before it arrives in the mould.”

Special screws, measuring between 14mm and 45mm in diameter, with a sealing system at the shaft, are adapted to the material. Currently, the LSR package is available on IntElect machines ranging from 50 to 180 tons. Other special features within the LSR package include a spring-loaded non-return valve to avoid uncontrolled backflow of material, a shut off nozzle specifically designed for LSR, plus a controlled vacuum sequence to extract air from the moulds cavities and to prevent air traps inside the LSR-parts.

Additionally, Sumitomo (SHI) Demag’s Centre Press Platen ensures high rigidity and uniform distribution of the clamp force to ensure more balanced pressure distribution while the robust linear guidance system controls the highest level of platen parallelism.

As an IntElect system, the machine features an advanced mould sensor safety system (activeProtect). Additionally, IntElect users can benefit from enhanced control of injection pressure up to ejector force graph.

Collaborating with LSR Masters

Critical to the entire processing cell is the specialist periphery equipment. Sumitomo (SHI) Demag intentionally selected LSR partners regarded as the most innovative, who all share a similar focus on precision.

Nexus created the concept and designed the four-cavity LSR light guide mould on show at K-2019. The company also supplied the mixing and dosing unit and full downstream demoulding automation.

Like the IntElect, the latest generation of the Nexus ServoMix (Z200) dosing machine, which is also being unveiled at K-2019, features a highly efficient servo drive. The continuously performing pump system stabilises the dosing and ensures a precise mixing ratio, irrespective of the dosing volumes. The unit also performs an uninterrupted venting of the LSR raw material using the company’s new Splitnex technology to eliminate air before it is fed into the machine and finally into the article.

To optimise the quality of LSR components, Nexus also installed its Timeshot cold-runner control technology. Enabling direct control of each individual cavity via a needle valve gate, this ensures the filling of each mould cavity is balanced. All controlled via a browser-enabled device for optimal set up.

German optical component expert Innolite supplied the diamond-machined mould inserts. Innolite’s inserts guaranteed the surface on each lens light was repeatedly blemish and scratch free, ensuring best optical performance of the whole head light.

For the exhibit, Dow supplied its specifically for optical application optimised silicone rubber. Created especially for LED lamp and luminaire applications, its high thermal stability retains high transparency, even in harshest of environments.

“Partnering with such companies, underpins our commitment to the LSR moulding market,” highlights Thomas who was hired by Sumitomo (SHI) Demag to head up the company’s LSR development hub based in Schwaig, Germany.

Matrix LED automotive lights are just one LSR application where, according to market research[1], significant growth is forecast. The adaptive headlight segment is expected to grow at the fastest rate between now and 2023, driven by high demand in Europe and Asia Pacific.

Thomas adds: “This is highly sophisticated technology, comprising complex optical surfaces where light is guided through the micro-milled polished surfaces. Connecting a camera control system, individual LEDs are switched on and off to ensure road users aren’t blinded by a full beam or to highlight a particular road obstacle. Right now the technology is confined to premium vehicles, but in the future these headlights could become more mainstream.

“To be involved in such an innovative LSR project when this technology is still in its infancy is testament to Sumitomo (SHI) Demag’s anticipation of future trends.”

A recent study by Polaris Market Research[i] has forecast that the global silicone elastomers markets will be valued at USD 9.34 billion by 2026. This rapid growth means that LSR is fast becoming the material of choice for specific applications in the digital electronics and automotive segments.

Another Sumitomo (SHI) Demag IntElect LSR moulding machine will be showcased at K-2019, with SMP Moules using an LSR optical material to create a magnifying glass on a key chain. Hall 1, Booth 40.

Discover more at the Sumitomo (SHI) Demag stand, Hall 15, Booth D22, 16 to 23 October 2019.

Sumitomo (SHI) Demag Plastics Machinery GmbH

Sumitomo (SHI) Demag has shaped the development of the plastics industry from its very beginning. As a specialist for injection moulding machines for plastics processing, Sumitomo (SHI) Demag and its Japanese parent company are leading the industry.

The global development and production network of Sumitomo Heavy Industries and Sumitomo (SHI) Demag is comprised of four facilities in Japan, Germany and China with more than 3,000 employees. The product portfolio includes all-electric, hydraulic and hybrid injection moulding machines with clamping forces of between 180 and 15.000 kN. With more than 125,000 installed machines, Sumitomo (SHI) Demag is present in important global markets and ranks among the largest manufacturers of injection moulding machines in the world.

At Sumitomo’s headquarters in Chiba, Japan, the company manufactures machines with clamping forces in the small to medium range. Nearly 95 % of all delivered machines are equipped with an all-electric drive concept. Sumitomo (SHI) Demag’s German facilities in Schwaig and Wiehe produce the Systec Servo range with hybrid drive as well as the El-Exis SP and Systec SP range of high-speed, high-performance machines. The all-electric IntElect range for international customers is also being produced in Germany.

As early as 1998, Sumitomo (SHI) Demag set up its first production site in Ningbo/China. In 2015, the Chinese subsidiary Demag Plastics Machinery (Ningbo) Co., Ltd. installed a new facility with a 13,000 m² floor space. It is earmarked for the production of the Systec C range with clamping forces of between 500 and 10,000 kN for the Asian market.

In addition to injection moulding machines, Sumitomo (SHI) Demag offers customised and standardised systems for the part handling automation, technical and process solutions for special applications, tailored services and service concepts as well as a range of financial options to support investment in injection moulding machines.

With its comprehensive sales and service network of subsidiaries and agencies, Sumitomo (SHI) Demag is present in all major markets.

Press release issued for Sumitomo (SHI) Demag Plastics Machinery GmbH by: Lucy Benbow , Sarah Willington