CMS sensor systems for condition monitoring (CMS = condition monitoring system) have been in use in large-scale production plants for many years to minimize profit losses through production downtimes and costly maintenance work. Application examples are rotary kilns in cement plants, conveying systems in mining, pipe-jacking machines in tunnel construction, power plant turbines or wind power stations. Thanks to recent progress in sensor technology and increasing availability of high-speed data networks, CMS systems are now becoming interesting also for less expensive capital goods such as injection molding machines. Here, Wittmann Battenfeld has blazed the trail and offers CMS equipment as an optional extra for its injection molding machines.

In contrast to time-oriented maintenance (preventive maintenance), where machine parts are replaced at fixed intervals regardless of their actual condition, condition monitoring (CM) is based on continuous observation of the parts’ condition (predictive maintenance). The latter approach offers the advantage that replacements depend exclusively on the actual degree of wear and functionality of the parts. The superiority of condition monitoring over preventive maintenance is inherent in the method itself. For any damage occurring in the course of a

maintenance interval normally remains undetected and may therefore even lead to a total breakdown, while the problem could often be remedied at little expense if it was detected in time. The costs for unplanned repairs incurred in this way and the loss of profit caused by the machine standstill are generally higher than the costs of a condition monitoring system. This is all the more important; the more closely the production is linked to a just-in-time supply chain, as is the case, for example, in injection molding production for automotive suppliers. (fig.1)

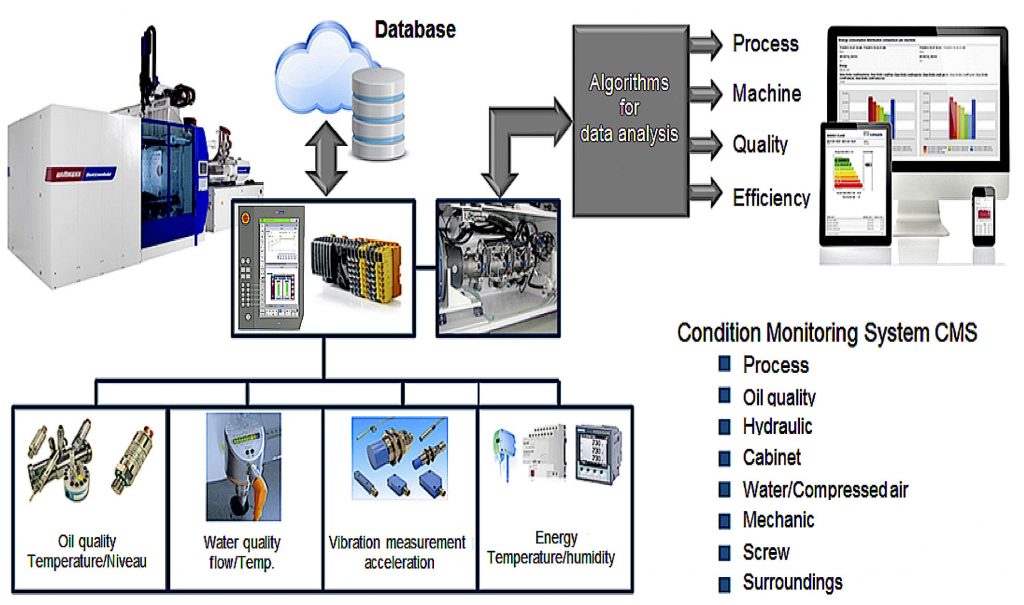

Fig.1: A condition monitoring system for condition-oriented scheduling of maintenance work increases plant availability in a demand-oriented “just-in-time” supply chain.

Comprehensive CMS package available

At the K 2016, WITTMANN BATTENFELD introduced a condition monitoring system (CMS) which is available as an optional equipment package for injection molding machines. It accesses the values measured by already existing as well as additional sensors installed for this purpose and passes on these data to a recording system.

Fig .2: The WITTMANN BATTENFELD CMS concept of condition data collection by sensors and subsequent data processing as the decision-making basis for maintenance work

The CMS system actually monitors the following (fig. 2):

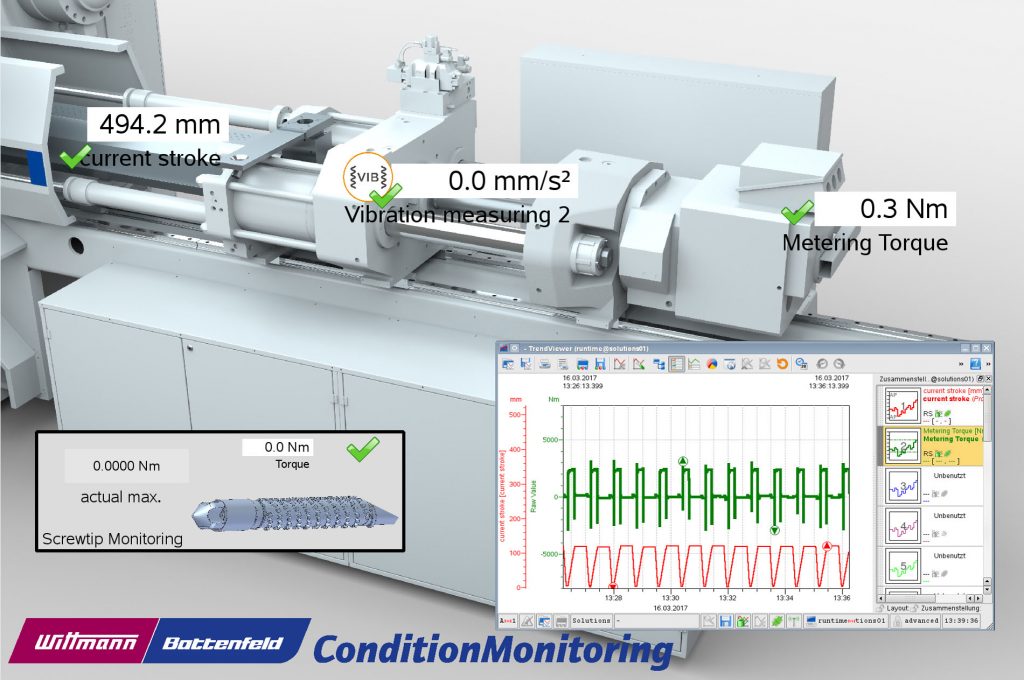

Fig.3: Display example of condition monitoring of the screw drive and check valve function

Condition data processing on three levels

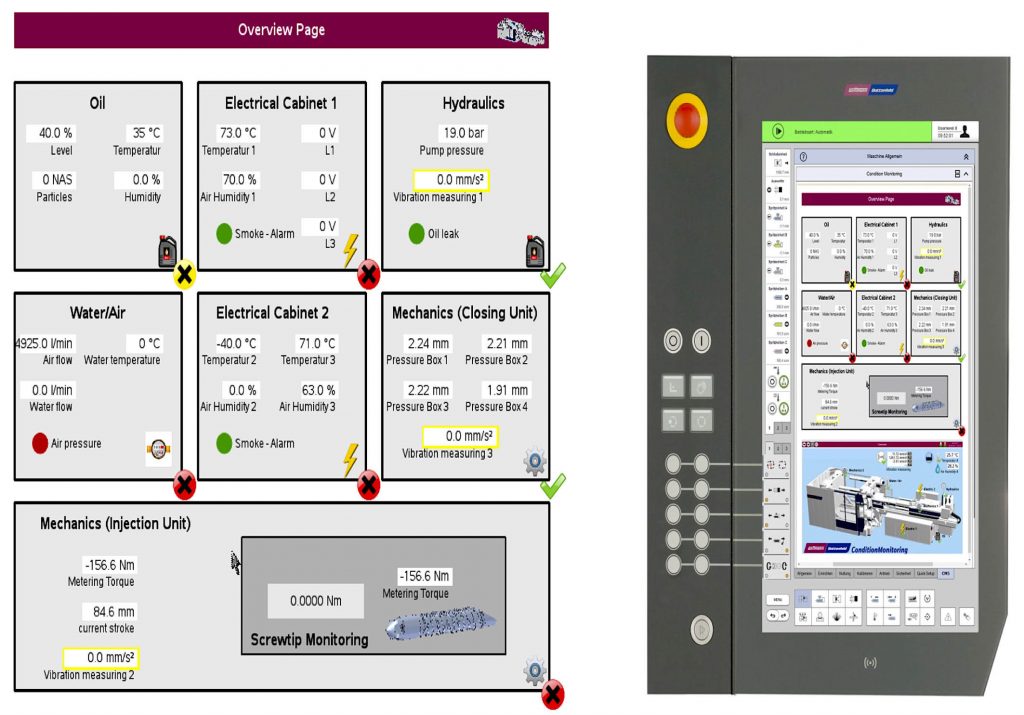

The data (temperatures, moisture, signals from the smoke detector inside the electric cabinet) are collected on the machine partly cycle-synchronously and partly dependent on time, and subsequently transmitted to the CMS computer for evaluation. On the machine, the current condition data are displayed compactly on an overview page of the machine’s B8 control system (fig.4). Deviations from pre-set reference values (temperature ranges, air pressure, and smoke detector signals) are visualized by green/red traffic light indicators.

Fig.4: Overview of condition values on the B8 machine control system

The heart of the CMS system is the CMS computer. It is part of a production control system. It communicates with the injection molding machines and draws the measurement data, collects and saves them for possible later backtracking. The CMS software processes the measurement data into trend-tracking models.

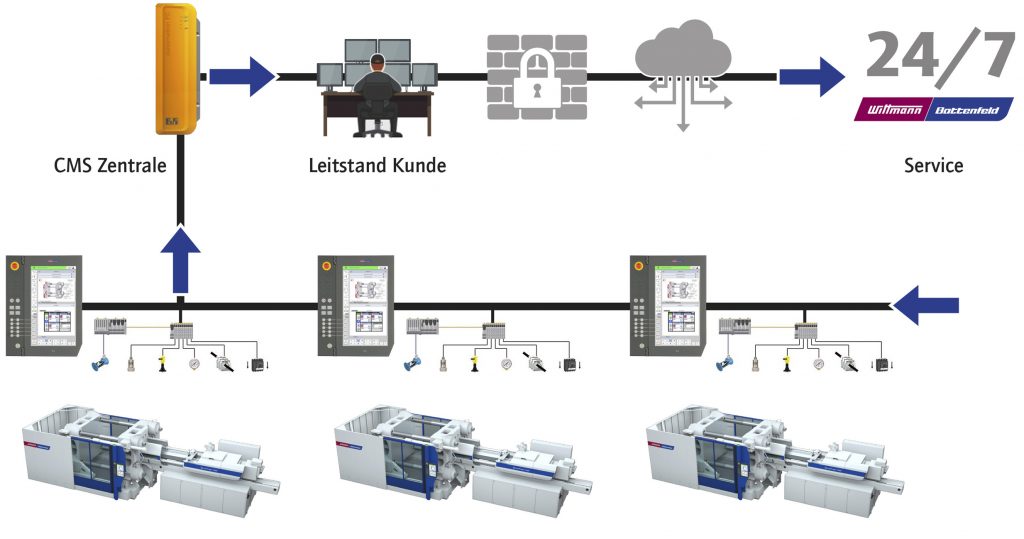

A CMS control station is able to monitor up to 50 machines simultaneously and pass on advance warnings to maintenance staff by email (fig.5).

Evaluation of the data is based on generally recognized quality standards, such as the NAS (National Aerospace Standard) oil quality assessment1638 or the oil purity rating according to ISO-4406. Empirical limit values are used for judging air and oil pressure values, temperatures or the closing behavior of the check valve. In addition, the vibrations of components exposed to wear are measured by vibration sensors and evaluated by analysis algorithms (see again fig. 2).

Besides current status information, the CMS software also delivers trends indicating changes in functional values. These provide the basis for decision-making by maintenance staff. Should no sufficiently qualified or experienced personnel be available on site for correct interpretation of this decision-making tool, it is also possible to outsource the interpretation of the data to a WITTMANN BATTENFELD service center via online networking and have the necessary maintenance work initiated from there. This service can be supplied by the WITTMANN BATTENFELD service organization (fig.5).

Fig.5: The monitoring data from up to 50 machines can be collected on one condition monitoring host computer. Where the measured values exceed or fall below tolerance margins, the calculated data trends trigger signals which must be correctly interpreted and followed up by appropriate action on the part of qualified maintenance staff.

Summary

Condition-oriented machine maintenance offers better failure protection than servicing in fixed regular intervals or a preventive maintenance concept since, due to lack of information, malfunctions developing between maintenance sessions (loose screws, gradual failure of bearings) with a risk of sudden total breakdown are very hard to detect. This is why a CMS system is a useful contribution to improving failure protection of production processes, primarily and in particular for just-in-time production chains. The cost of implementing a condition monitoring system is already compensated for by preventing only a few days of production standstill.

About WITTMANN BATTENFELD

WITTMANN BATTENFELD is a member company of the WITTMANN Group with its headquarters and production plant located in Kottingbrunn / Lower Austria. Its corporate focus is on plastics injection molding technology, covering the entire range of machinery from micro injection molding machines with 5 tons clamping force up to large machines with 2,000 tons clamping force. The company’s product portfolio is rounded off by extensive additional technology packages, e.g. for multi-component, foam or fiber composite injection molding. In conjunction with the portfolio of the WITTMANN Group, a leading manufacturer of robotics and auxiliary equipment for material supply, WITTMAN BATTENFELD is able to supply complete injection molding systems including Industry 4.0 data networks.

Press release from WITTMANN BATTENFELD