Molding Solutions, a strategic business unit within Barnes and pioneer of new technologies in injection molding, and INEOS Styrolution, the global leader in styrenics, today announced that they will collaborate on a sustainable ABS[1] solution that will make molding biomaterials and sustainable plastics easier.

Molding Solutions and INEOS Styrolution will bundle their extensive expertise and unique technologies to make mechanically-recycled ABS solutions easier to process and achieve repeatable molded product quality with INEOS Styrolution’s Terluran® ECO MR-50/70 materials, in particular.

Yohann Bach, Product Director ABS Standard EMEA, INEOS Styrolution, says: “We are convinced that our Terluran ECO is the best mechanically-recycled ABS in the world. It offers identical properties to the respective native material. We are excited to offer it with a 50% recycling content (MR50) or with a 70% recycled content (MR70).”

Dr. Stefan Kruppa, Vice President of R&D for Molding Solutions, adds: “With our unique technology, we are able to expand our molding capabilities of post-consumer recyclate to meet the required product quality. Our aim is to enable customers to achieve the best results in the injection molding process with recycled ABS.”

Experts from Molding Solutions’ connected brands Priamus®, männer™, and Gammaflux® will be available at the Molding Solutions Network Open House at Manner USA Inc. in Lawrenceville, Georgia, for a live demonstration of the process and to discuss details with engineers and molders who work on next-generation product designs.

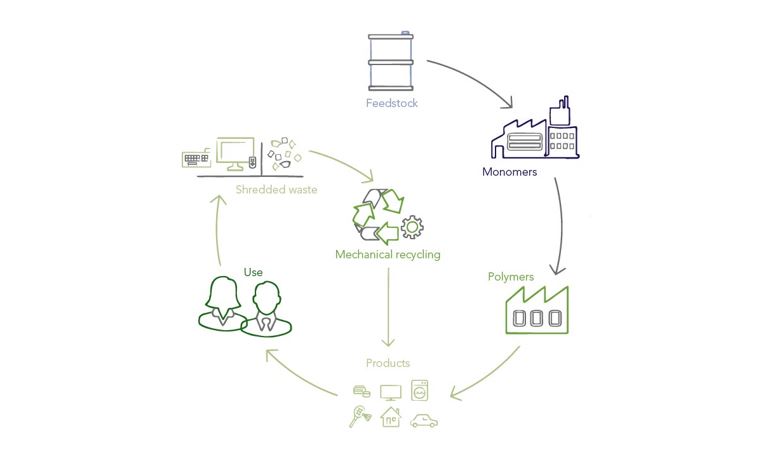

Terluran® ECO GP-22 grades were the first contribution from INEOS Styrolution to meet the INEOS pledge to incorporate at least 325kt/year of recycled materials into its products. The two new grades, Terluran® ECO GP-22 MR50 and Terluran® ECO GP-22 MR70, contain 50 and 70 percent of recycled post-consumer waste electrical and electronic equipment (WEEE), respectively. Both grades will be available in black. Product properties of the grades match the mechanical property profile of their non-recycled counterparts.

About Molding Solutions

Molding Solutions is a strategic business unit within Barnes, which includes leading plastic injection molding brands for tooling, hot runners, and controls: Synventive®, Thermoplay®, männer™, FOBOHA®, Priamus®, and Gammaflux®. Molding Solutions’ comprehensive portfolio of advanced technologies and value-added services delivers best-in-class solutions where demanding specifications are required by global customers across a broad spectrum of applications.

For more information, visit Barnes Industrial – Molding Solutions for Sustainable Plastics Applications (barnesgroupinc.com)

About INEOS Styrolution

INEOS Styrolution is the leading global styrenics supplier, with a focus on styrene monomer, polystyrene, ABS Standard and styrenic specialties. With world-class production facilities and more than 90 years of experience, INEOS Styrolution helps its customers succeed by offering solutions, designed to give them a competitive edge in their markets. At the same time, these innovative and sustainable best-in-class solutions help make the circular economy for styrenics a reality. The company provides styrenic applications for many everyday products across a broad range of industries, including automotive, electronics, household, construction, healthcare, packaging and toys/sports/leisure. In 2021, sales were at 6 billion euros. INEOS Styrolution employs approximately 3,600 people and operates 20 production sites in ten countries.

More information: www.ineos-styrolution.com