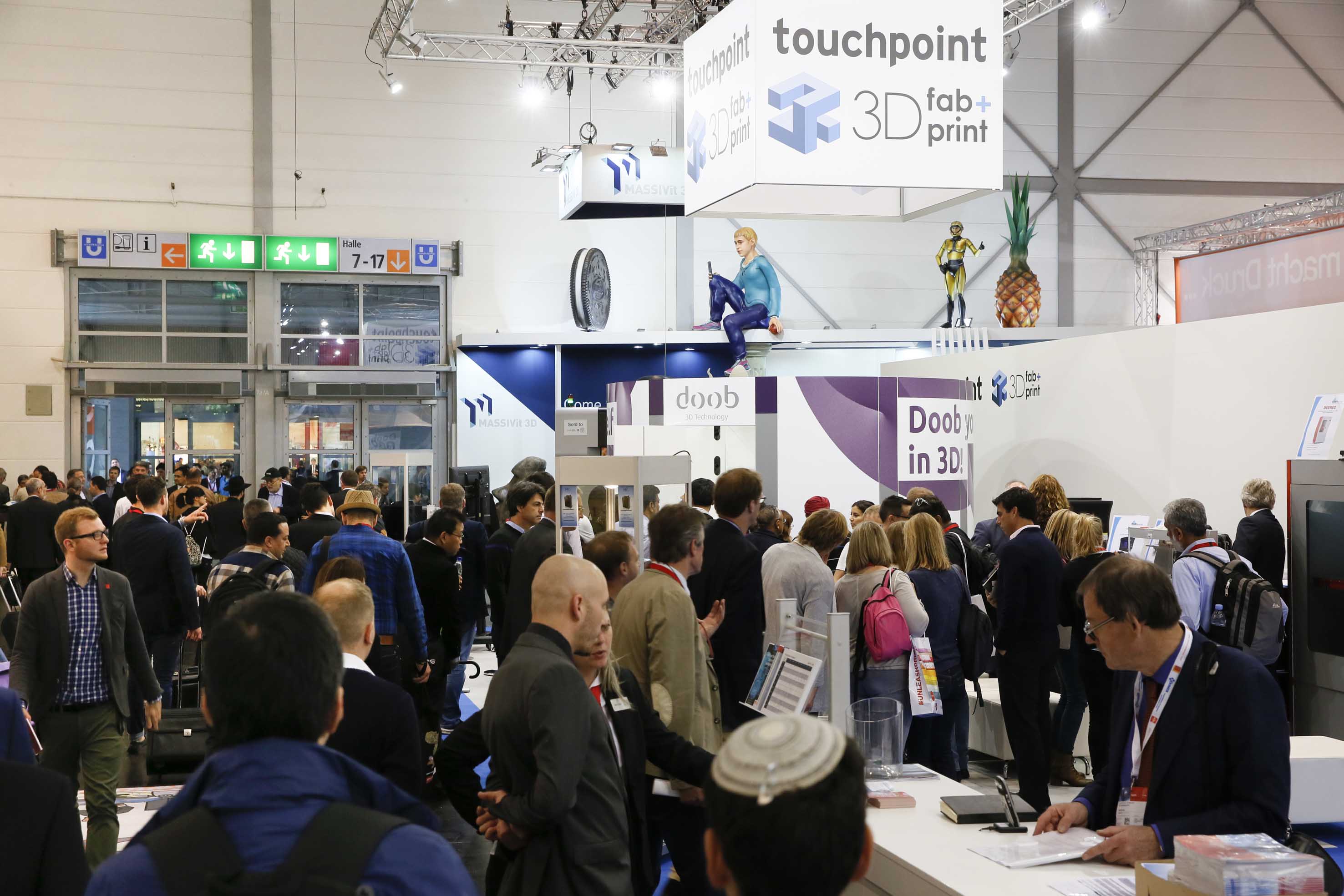

Frankfurt, August 29, 2019 – The Additive Manufacturing Working Group (AG AM) within VDMA will be hosting a ten-day conference at the world’s leading trade fair drupa 2020 (June 16 – 26, 2020 in Düsseldorf). “We see drupa touchpoint 3D fab+print as the ideal setting to show trade visitors and exhibitors the great technological and economic potential of industrial 3D printing and to give them an insight into the current state of the art”, explains Dr. Markus Heering, Managing Director of AG AM. A total of 80 expert presentations are planned, which will be spread over two two-hour program blocks per day.

User- and practice-oriented conference program

Messe Düsseldorf is expecting more than 250,000 visitors, 1,800 exhibitors and as many journalists from over 180 countries to attend drupa 2020. Because their focus lies in technologies, processes and business models in the printing, media and packaging sectors, AG AM is focusing the content of the lecture programme on application-related topics and a mix of introductory and in-depth lectures.

“We would like to introduce interested drupa visitors to additive technologies and their advantages for the manufacturing of machine parts, spare parts or tools and give them realistic assessments of the current and future possibilities of additive processes”, explains VDMA project manager

Dr. Irene Hassinger the objectives of the conference. The first programme items have already been defined. Prof. Gert Witt, head of the Chair of Production Technology at the University of Duisburg-Essen, and Dr. Stefan Kleszczynski, head of the Rapid Technology Center (RTC), will introduce the additive technology and its future potential.

Witt has been working on additive methods since the 1990s. In recent years, technology has increasingly found its way into industrial applications. The VDMA’s working group Additive Manufacturing aims to accelerate this industrialization by developing binding quality standards and the basis for comprehensive automation along the process chain. 150 member companies are involved, including leading suppliers of systems for additive processing of metals, plastics and other materials, suppliers of components, materials, software and automation technology, as well as industrial users from a wide variety of industries and leading research institutes. Being part of the working group Additive Manufacturing, experts from the AM specialist Materialise and Krause Dimatec GmbH have agreed to give presentations at the drupa conference.

Practically relevant for print shops and press manufacturers

“One focus of our initiative is the automation and networking of additive process chains,” explains Hassinger. These aspects will also be discussed at the conference – but above all, there will be practitioners pointing out concrete possibilities. For this purpose, the lectures will illuminate individual process steps along the chain, starting with solutions for additive-optimised designs and constructions, through the additive construction phase and the materials that can be used, to the possibilities of post-processing and finishing.

The focus is on applications in the field of printing and paper technology. This includes the additive production of high-performance components and spare parts for printing presses or the possibility for printers to expand their portfolio to include 3D printing. The Cologne-based plain bearing specialist IGUS and Bielefeld-based Krause Dimatec GmbH will be demonstrating as an example how additive manufacturing can be used to bring individualized and weight-optimized components to customers quickly and cost-effectively – and at the same time significantly increase the service life of highly stressed components through additive-optimized designs and the right choice of materials. Especially with a view to high-speed processes in the printing industry, additive-optimized lightweight constructions promise advantages in terms of precision, process speed and energy consumption.

“With its 150 member companies from all areas of 3D printing, the VDMA working group Additive Manufacturing is the ideal partner to fill the conference programme of our drupa touchpoint 3D fab+print with relevant content,” says Sabine Geldermann, Director drupa & Global Head Print Technologies at Messe Düsseldorf. The drupa team is looking forward to the cooperation and a highly interesting conference at drupa 2020: “Our goal is to achieve the highest possible relevance for the drupa target group. Anyone who would like to contribute to this with an exciting topic of practical relevance is welcome to contact us,” says AG AM Managing Director Heering.

The preliminary lecture program of the drupa touchpoint 3D fab+print is structured as follows:

1. Applications

|

2. Technology

|

Press release from VDMA Additive Manufacturing