KP Linpac purchases a third IRD from KREYENBORG and expands its production of food packaging

The possibility to crystallize and dry varying PET input materials quickly and in one step, has convinced KP Linpac right from the beginning. Therefore, the manufacturer of high-quality food packaging materials has just placed an order for his third Infrared Rotary Drum of KREYENBORG GmbH & Co. KG, located in Senden, Germany. With this new production plant, KP Linpack expands its production capacities for thermoformed PET packaging solutions at the company site in Beeskow substantially.

Since 2017, Linpac has been part of the world-wide operating Klöckner Pentaplast Group (KP), a leadingmanufacturer of films and packaging solutions with around 6,300 employees and a yearly turnover of 2bn Euros. In Germany, KP Linpack produces PET sheet and, in a second step, thermoformed trays forfoodstuff at both its company sites Ritterhude and Beeskow. In this activity, the plastics producerattaches much importance to the conservation of natural resources, flexibility and efficiency. These are precisely the benefits offered by the Infrared-Rotary Drum made by Kreyenborg GmbH. Arno Jansen, the Project Extrusion Manager from Ritterhude, who ordered the first IRD spontaneously around 5 years

ago, after successful trials effected in the test facility in Senden, comments: “The possibility to crystallize and dry virgin material and ground stock in a first process step quickly and efficiently, fits into our production plants perfectly.” The Infrared Rotary Drums are so perfectly suited equipment that we have been using two of them in Ritterhude and that no other solution could even be considered for the expansion of our capacities in Beeskow either.” The third IRD of the same specification will be delivered at the beginning of 2019.

Particularities of multilayer sheet applications

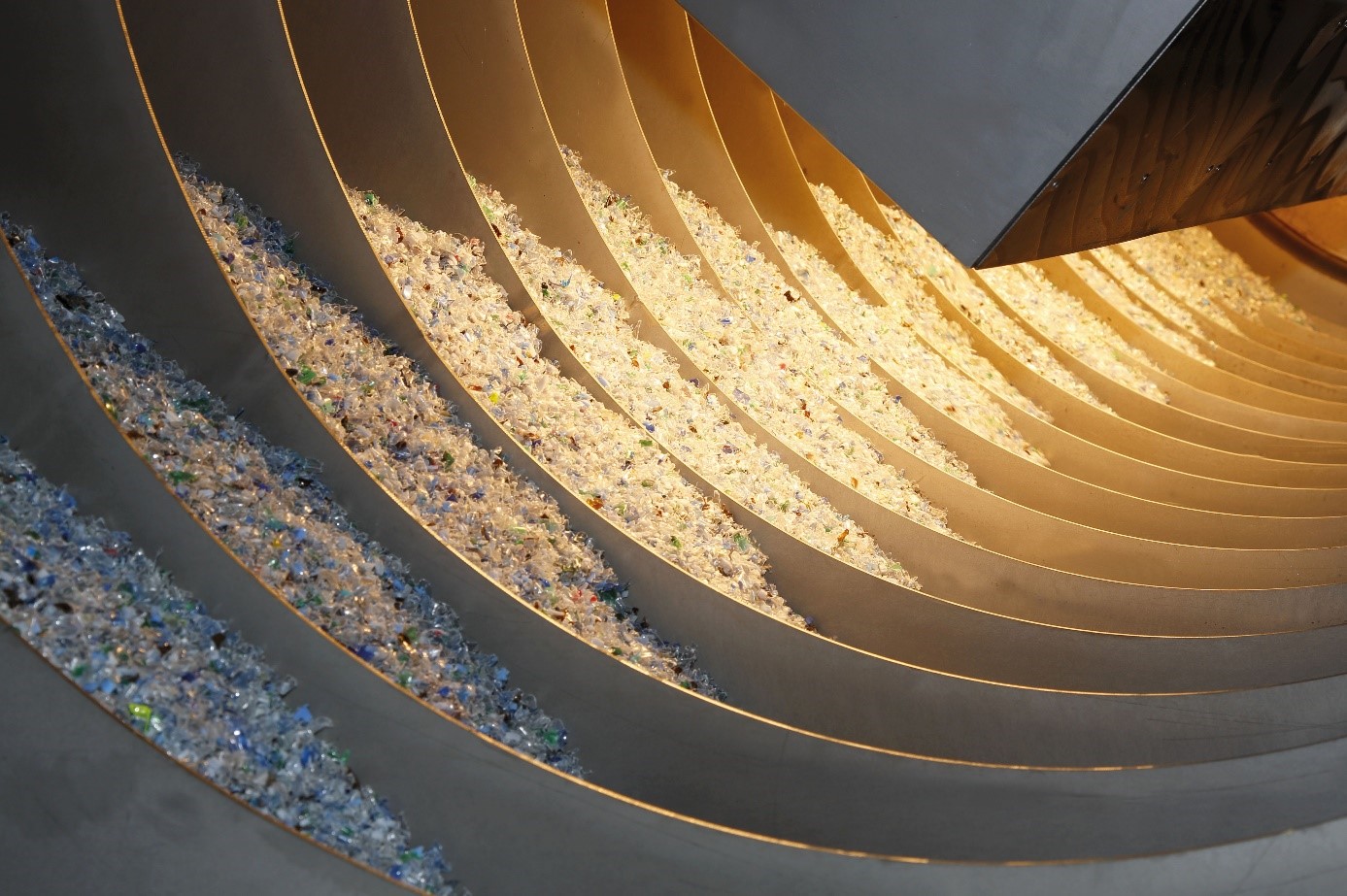

An IRD for KP Linpack achieves a continuous drying capacity of 800 kg/h. In these IRD, the material fed in is circulated and conveyed on a permanent basis due to the rotary movement of the tube. “The low filling level in combination with the high circulating speed make the IRD a very efficient crystallization and drying unit, which does not only work more quickly than ordinary desiccant air dryers, but also needs less energy and is much more flexible as regards the materials used,” explains the project manager in charge at Kreyenborg, Marcus Vogt. ‘Flexibility’ means for KP Linpac to be able to process not only ground punching scrap, but also edge trims from sheet production and variable mixtures from both of

them. Infrared light ensures material heating in the IRD, virtually from inside out. In this way, a crystallization effect is achieved at roughly 135°C in the first step and material drying is achieved at roughly 170°C in the second step. The final result achieved is a perfectly prepared input material to be

used for renewed film production. The fact that KP Linpac produces PET film with a sealing layer made of PE does not represent any problem in this respect. The non-stick coating of the IRD prevents the risk of the lower melting PE keeping stuck with the tube coils and the constant mixing ensures that the material remains free flowing and can be fed back again into the extrusion process without any problems. However, flexibility also means that material changes, for example in case of a colour change, can be carried out quickly and in an uncomplicated manner. “The IRD is completely cleaned within only two hours and can be used again immediately by simply using a start-stop button,” explains Marcus Vogt in giving another crucial advantage.

The plastics industry has recognized the advantages of Infrared-Rotary Drums long since. Several hundred units have been installed world-wide in PET and other plastics applications. At the same time, their area of application is also as diversified as their design. They are not only used for simply drying processes, but also for crystallization tasks and combinations of these. KREYENBORG’s product range of machines does not only include continuously working standard models for outputs of 50 to 2,500 kg/h, but also a batch system and customized designs.

www.kreyenborg.com