A speed profile can be set up for the opening and closing movement of the valve pins. Up to 7 pin positions per nozzle can be run at different speeds. The maximum 7 positions can be variably adjusted as required on the opening and closing movement. The gentle switching of the second nozzle reduces the loss in pressure of the first nozzle.

The staggered, hydraulic control avoids a possible, short-term melt stagnation and thus possible surface defects. Simple operation with easy to read display

The profiTEMP+ VCON controls the valves during cascade injection moulding and can be combined in one housing with temperature control. The touch screen operation shows the processes, displays the individual sealing times and allows the data to be read out via USB for documentation. Whether you control the valve gate nozzles conventionally, opt for the high-end solution with varioFill advanced or decide on a combination of the two, the profiTEMP+ VCON is the perfect solution.

Unbeatable value for money

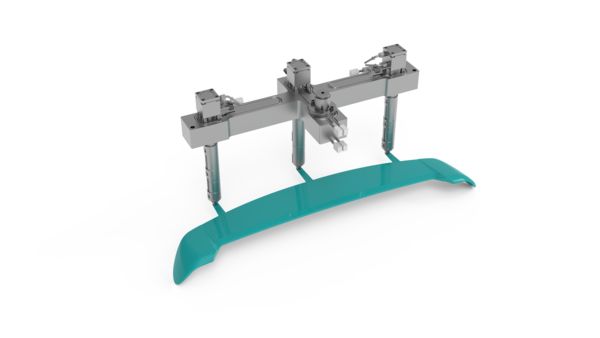

varioFILL advanced offers an uncomplicated solution based on a hydraulic valve gate system with innovations in the gate design and hydraulic control. You can avoid complicated electronics which require time consuming and intensive training for operation. Intuitive and easy to use, the varioFILL advanced offers the maximum results at the minimum cost.

Hydraulic hot runner systems can also be easily and economically fitted to be controlled by varioFILL advanced.

Source: Meusburger