SIGMASOFT® helps mold makers to identify the right tool alloy during the design stage

For highly technical parts the optimum mold configuration is paramount to produce high quality parts in robust processes. With the help of SIGMASOFT® Virtual Molding mold makers test their mold concepts upfront on a virtual injection molding machine. In this way, they identify the ideal mold configuration before machining the steel.

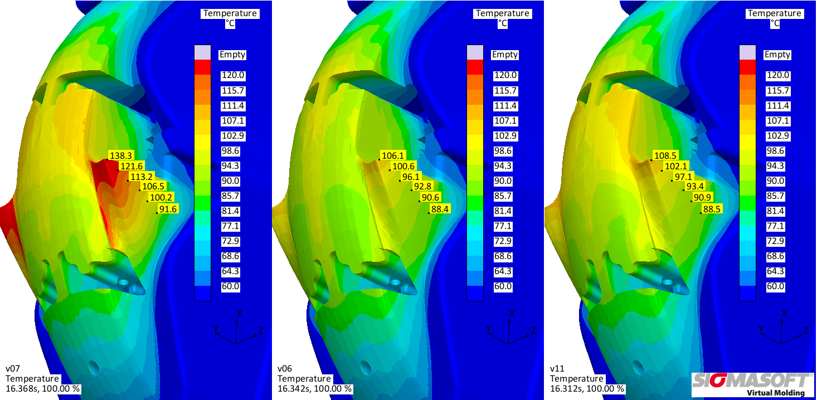

Temperature distribution on the mold core for the initially planned common mold steel (left), as well as the core inserts out of CuBe B2 (middle) and Moldmax HH (right)

Finding the Optimum Configuration for Injection Molds

Aachen, April 11th, 2019 – At Moulding Expo 2019 (May 21st to 24th, 2019, in Stuttgart, Germany) SIGMA Engineering GmbH from Aachen, Germany, exhibits their SIGMASOFT® Virtual Molding technology. In hall 7 at booth 7E15 SIGMA showcases how the software helps to analyze and evaluate injection molds and their tempering concepts from the early design stage. It supports the user in identifying the ideal combination of mold alloys and tempering layout. Thus, the software allows mold makers to built molds that produce good parts from the first trial on the machine.

In an example case for an automotive application the mold initially was planned with a common mold steel. To avoid costly iterations of the mold, the whole configuration – including all mold components and their respective alloys – was set-up in SIGMASOFT®. Working as a virtual injection molding machine the software calculated an initial heating-up phase as well as several injection cycles to reach a thermal steady state. The analysis of the thermal steady mold revealed hot spots in some of the mold cores (Fig. 1, left), where the temperature got up to 30 °C higher than in the rest of the cavity. To reach a more homogenous distribution, different possible solutions were discussed and evaluated with the help of SIGMASOFT® Virtual Molding.

Due to the overall configuration of the mold the preferred solution was to exchange the common mold steel with a high conductivity alloy instead of introducing additional cooling channels. Therefore, virtual trials were conducted with mold inserts out of CuBe B2 and Moldmax HH. As in the initial analysis, these virtual trials were calculated with a heating-up phase followed by several molding cycles to reach a thermal steady state. In the end, the temperature distribution on the cores with all three materials was compared. Both high conductivity alloys showed a significantly improved and more homogenous temperature distribution (Fig. 1, middle and right). As the achieved temperatures of both high conductivity alloys were in the same range, both provided a sufficient solution for avoiding the hot spots. Based on the simulation results, the mold could immediately be built with high conductivity cores to supply the base for a robust process.

SIGMASOFT® allows its users to easily test and evaluate their planned mold configuration before the mold is built. With its help they identify critical temperature behavior and test solutions to improve the mold and make the injection molding process more robust. Thus, they save costs and avoid iterations on the mold during the trial-and-error on the machine.

SIGMA (www.sigmasoft.de) is sister company to MAGMA (www.magmasoft.de), the world market leader in casting process simulation technology based in Aachen, Germany. Our SIGMASOFT® Virtual Molding technology optimizes the manufacturing process for injection molded plastic components. SIGMASOFT® Virtual Molding combines the 3D geometry of the parts and runners with the complete mold assembly and temperature control system and incorporates the actual production process to develop a turnkey injection mold with an optimized process.

At SIGMA and MAGMA, our goal is to help our customers achieve required part quality during the first trial. The two product lines – injection molded polymers and metal castings – share the same 3D simulation technologies focused on the simultaneous optimization of design and process. SIGMASOFT® Virtual Molding thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved for over 25 years. A process-driven simulation tool, SIGMASOFT® Virtual Molding provides a tremendous benefit to production facilities. Imagine your business when every mold you build produces required quality the first time, every time. That is our goal. This technology cannot be compared to any other simulation approach employed in plastics injection molding.

New product success requires a different communication between designs, materials, and processes that design simulation is not meant for. SIGMASOFT® Virtual Molding provides this communication. SIGMA support engineers, with 450 years of combined technical education and practical experience, can support your engineering goals with applications specific solutions. SIGMA offers direct sales, engineering, training, implementation, and support, by plastics engineers worldwide.

Press release from Sigmasoft