Right now, during the Corona virus pandemic with closed retail stores, we are experiencing first-hand the tremendous importance of global digitization for the flow of information and online ordering. The rapidly rising number of applications worldwide clearly shows that the digitization of production equipment to exchange information between processing machines and auxiliary appliances is also becoming more and more important.

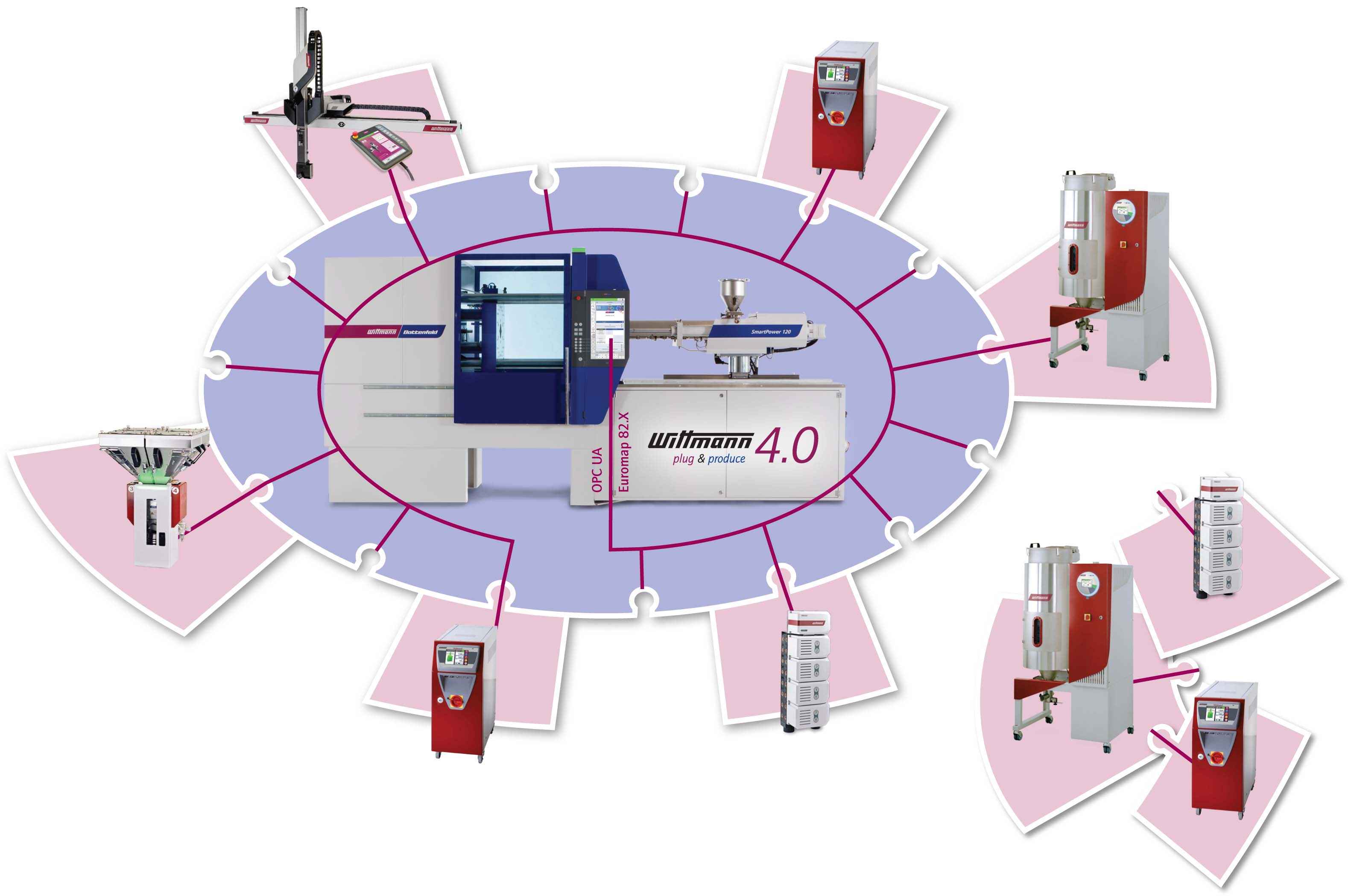

The WITTMANN Group is working on supporting and driving the efforts of modern injection molding companies towards digital integration of the entire production plant. This is why WITTMANN 4.0-compatible auxiliary appliances ordered from 1 April 2020 onwards can now be connected via OPC UA as standard and without any additional costs to suitably equipped WITTMANN BATTENFELD injection molding machines with B8 control systems.

The interconnection of WITTMANN BATTENFELD machines with WITTMANN appliances via WITTMANN 4.0 offers numerous advantages.

Optionally, the advantages of WITTMANN 4.0 can also be utilized outside the WITTMANN BATTENFELD production cell by connecting the machine and the auxiliary appliances to the TEMI+ MES system. In addition to the many standard functionalities of an MES system, TEMI+ supports the extended mold data set and the appliance preview.

The WITTMANN Group is a worldwide leader in the production of injection molding machines, robots and peripheral equipment for the plastics processing industry, headquartered in Vienna/Austria and consisting of two main divisions: WITTMANN BATTENFELD and WITTMANN. These two divisions jointly operate the companies of the WITTMANN Group with eight production plants in five countries. Additional sales and service companies are active in 34 facilities in important plastics markets around the world.

WITTMANN BATTENFELD pursues the further expansion of its market position as an injection molding machine manufacturer and specialist for state-of-the-art plastic processing technologies. As a supplier of comprehensive, modern machine technology in modular design, the company meets both present and future market demands for plastics injection molding equipment.

The WITTMANN product portfolio includes robots and automation systems, material handling systems, dryers, gravimetric and volumetric blenders, granulators, temperature controllers and chillers. With this diversified range of peripheral units, WITTMANN offers plastics processors solutions to cover all production requirements, ranging from independent production cells to integrated plant-wide systems.

The integration of these various segments under the umbrella of the WITTMANN Group has led to complete connectivity between the various product lines. This integration has greatly benefited plastics processing users, who are increasingly looking for seamless production, including automation and peripheral functions.

Source: fortuna.gr