The K 2019 exhibition saw WITTMANN BATTENFELD, together with its MES partner company ICE-flex, offer the plastics industry a ready-to-use and low cost single-machine MES solution called TEMIone.

MES solutions are an integral part of Industry 4.0 and have established themselves successfully in the plastics industry as information and control centers for the production monitoring and planning of injection molding machines. However, the initial hurdle for the decision to install a MES program in a company can be rather high. The reasons can include the often quite high cost for the complete package, the retrofitting of existing machines with standardized interfaces in order to communicate with the MES program, the organizational adjustment and training of company staff to make use of the system and the involvement of the internal IT department to set up the network and to adhere to the company’s security requirements.

In particular, companies with a relatively low number of injection molding machines may shy away from the financial and technical challenges of installing a MES solution in their plant. And this despite the many obvious advantages such a system would generate, namely, traceability of production data, calculation of the overall equipment efficiency, display of Key Performance Indicators (KPI’s) for root cause analysis of downtime, to name but a few factors.

The ready-to-use single-machine MES solution from WITTMANN BATTENFELD and partner ICE-flex, TEMIone, has been designed to precisely avoid all of these initial hurdles:

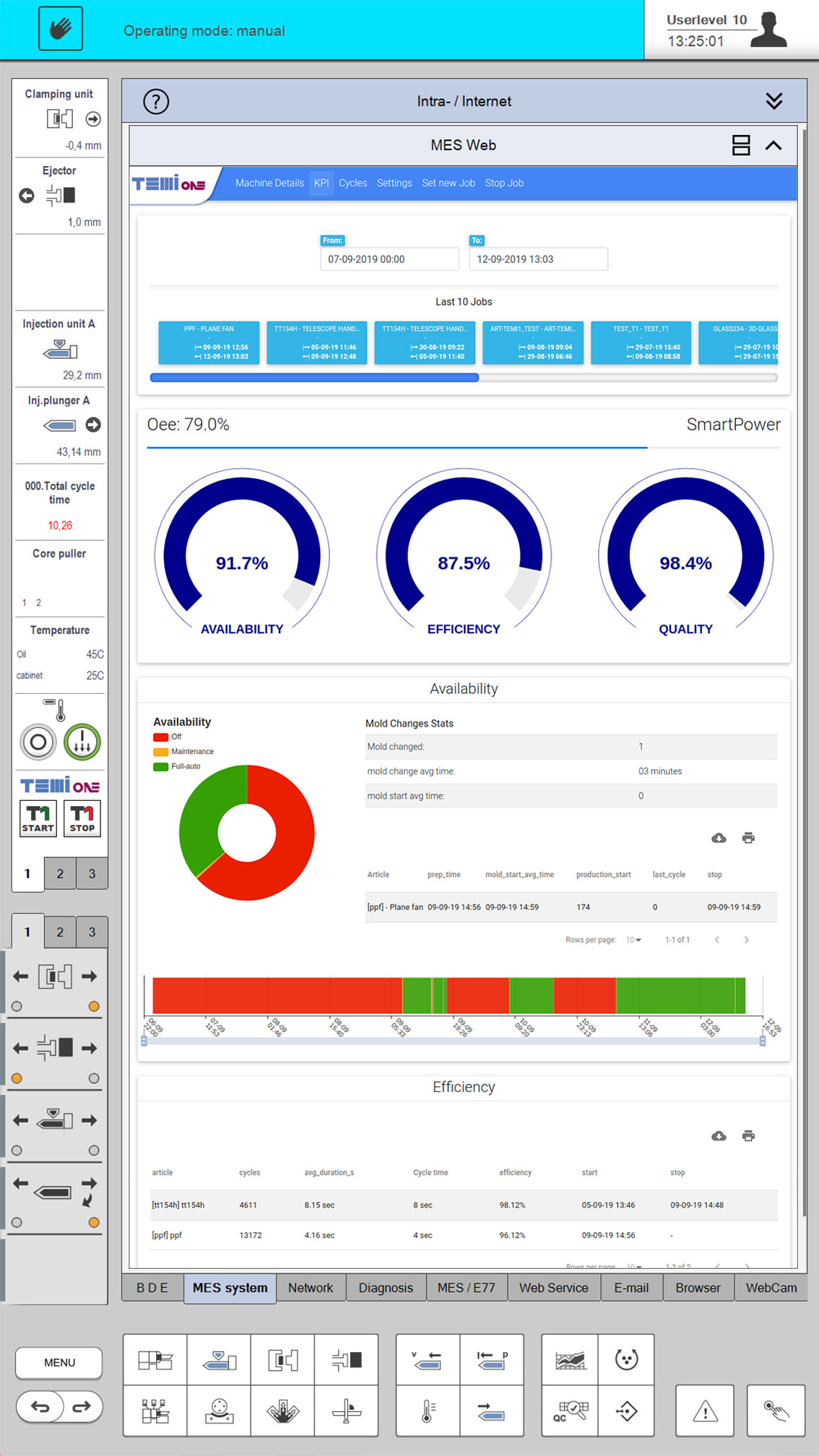

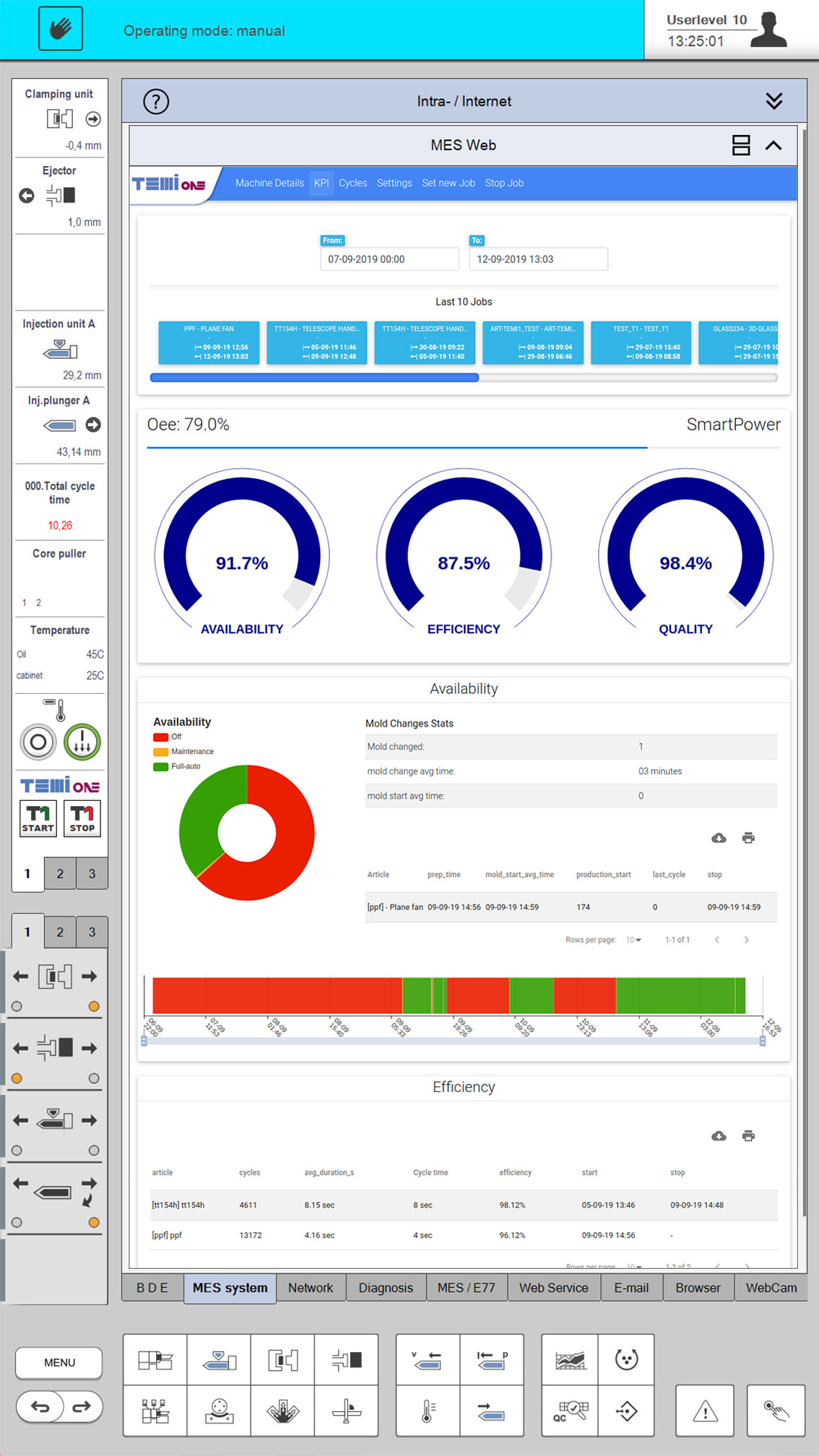

The new TEMIone is also easily accessible on the UNILOG B8 control of WITTMANN BATTENFELD injection molding machines. The main screen of TEMIone is the dashboard, and it gives a complete overview of the efficiency parameters.

Furthermore, TEMIone, as well as the advanced package TEMI+ for the entire shop floor can uniquely cover both injection molding machines and WITTMANN 4.0 auxiliaries around the molding machine. Therefore, a full and complete data acquisition and evaluation of the quality parameters of all devices involved in the production of a molded part is possible. All of the data recording can be initiated directly on the UNILOG B8 control screen of WITTMANN BATTENFELD injection molding machines. The data is stored as a standard on the on-board TEMI data server and can also eventually be extended to the outside via a USB port or even with a network connection to a remote folder if preferred.

The support of WITTMANN 4.0 means that all auxiliary equipment in the molding cell automatically logs in and out of the WITTMANN 4.0 based production in a “Plug & Produce” manner. Thus, the MES solution TEMIone/+ is always automatically informed about the composition of a work cell and can adjust the display on the screen, as well as the data storage accordingly and without user interaction. Another key advantage is the merging of error messages of all connected devices to a common error list. In addition, mold data settings including WITTMANN 4.0 equipment can be stored and retrieved. It is also possible to preview the mold data settings prior to downloading from the TEMIone server.

And – best of all – the TEMIone package comes at a very economical price, allowing even single requirements for data acquisition and storage in a company, e.g. for applications in the automotive, medical or pharmaceutical industry.

The WITTMANN Group

The WITTMANN Group is a worldwide leader in the production of injection molding machines, robots and auxiliaries for the plastics processing industry, headquartered in Vienna/Austria and consisting of two main divisions: WITTMANN BATTENFELD and WITTMANN. They jointly operate the companies of the group with eight production plants in five countries, and its additional sales and service companies are active with 34 facilities on all important plastics markets around the world.

WITTMANN BATTENFELD pursues the further expansion of its market position as an injection molding machine manufacturer and specialist for state-of-the-art process technologies. As a supplier of comprehensive, modern machine technology in modular design, the company meets both present and future market demands for plastics injection molding equipment.

The WITTMANN product portfolio includes robots and automation systems, material handling systems, dryers, gravimetric and volumetric blenders, granulators, temperature controllers and chillers. With this diversified range of peripheral units, WITTMANN offers plastics processors solutions to cover all production requirements, ranging from independent production cells to integrated plant-wide systems.

The syndication of the various segments under the umbrella of the WITTMANN Group has led to complete connectivity between the various product lines, for the benefit of plastics processors with an increasing demand for seamless integration of processing machinery with automation and auxiliaries.

For more informations visit fortuna.gr