At the K 2019 in Düsseldorf, WITTMANN BATTENFELD will present for the first time the COMBIMOULD version of its new VPower vertical machine series under the motto “Enjoy innovation” in hall 15, booth C06.

The new vertical machine model designed according to the PowerSeries concept was successfully launched by WITTMANN BATTENFELD at the beginning of 2019 in the sizes of 120 and 160 tons. Now this machine series is also available in the sizes of 220 and 300 tons with rotary table diameters of 1300, 1600 and 2000 mm.

In addition to extending the machine series upwards, the company has worked on the development of the multi-component version of the VPower. The latter will be presented to a broad public for the first time at the K 2019. From this year’s autumn onwards, all VPower machines will now also be available on the market in the COMBIMOULD version. The drive unit of the VPower provides the basic prerequisites for operation with two aggregates. In the standard configuration, the second hydraulic system is used for ejection during the injection molding cycle. But in multi-component applications, it powers the second injection unit, so that both injection units can always carry out injection and metering simultaneously. If the machine has been prepared for 2-component operation, it can either be ordered as a 2-component injection molding machine ex works, or be retrofitted with a second plasticizing unit later.

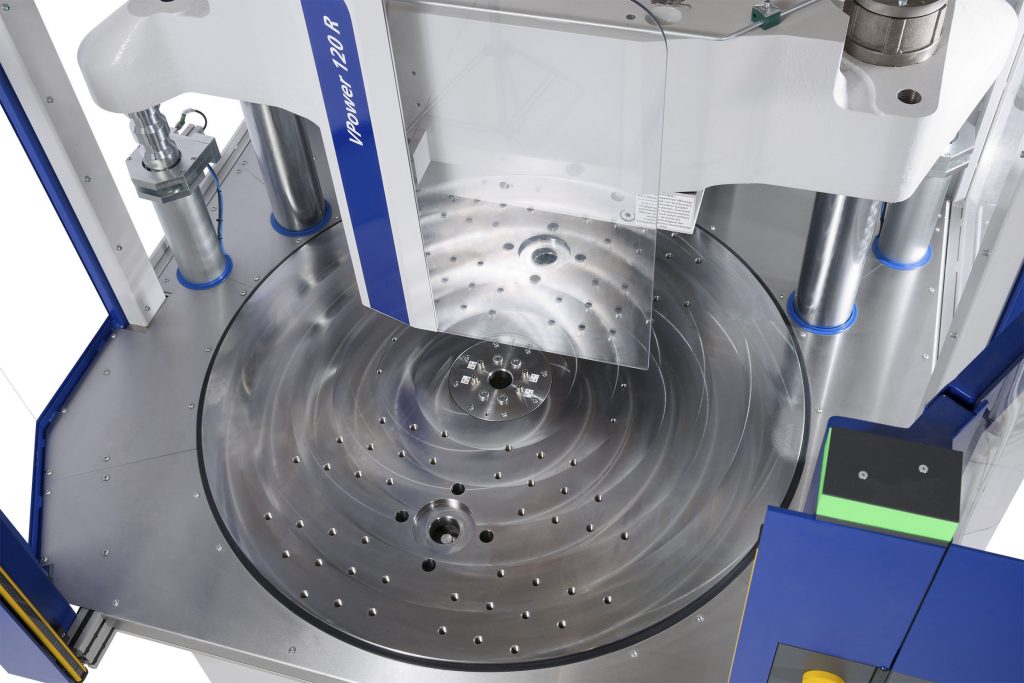

Round table available in diameters of 1300, 1600 and 2000 mm

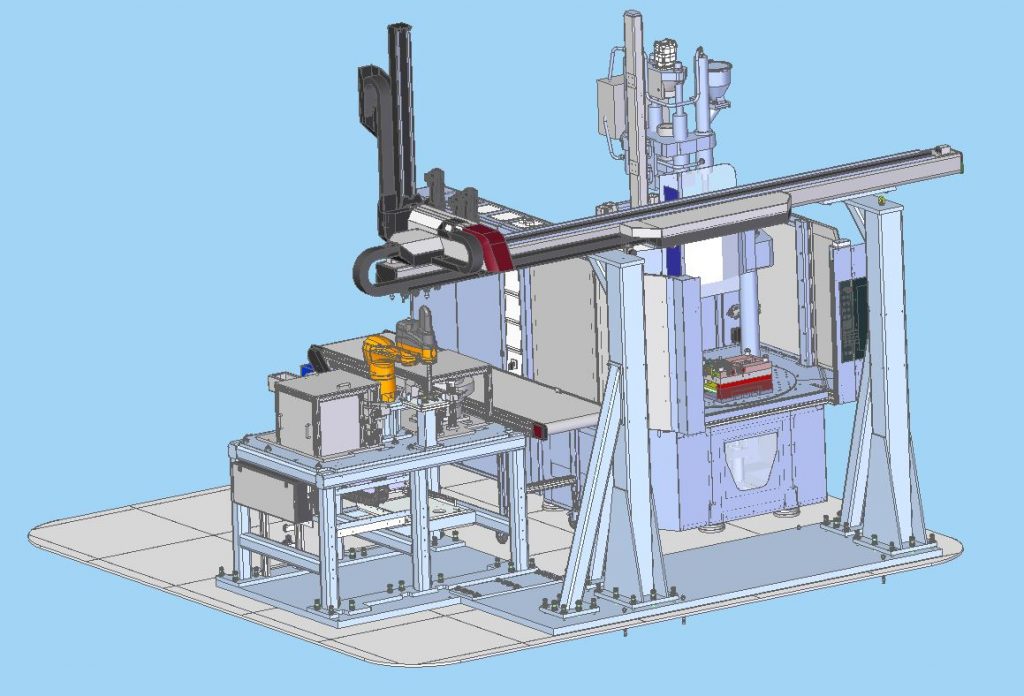

Drawing of the VPower 120/130H/210V COMBIMOULD with automation from WITTMANN BATTENFELD Deutschland in Nuremberg

The VPower distinguishes itself from its predecessor models above all by its innovative 2-tie-bar rotary table concept, which provides optimal accessibility thanks to dispensing with the middle tie-bar. The tie-bar-less rotation center leaves ample space under the rotary table for cooling water, hydraulic oil, compressed air and power supply connections. The generously dimensioned rotary tables are combined with a 2-tie-bar portal clamping unit equipped with two travel cylinders on the outside for fast opening and closing. The rotary tables are available with servo-electric drives for short rotation times and highly accurate positioning and are laid out for both oscillating 2-station operation and rotary 2-, 3- or 4-station operation.

The UNIFORCE compensation plate system between the horizontal beams of the clamping unit and the mold clamping area ensures even and gentle force transmission to the mold.

Plug for the automotive industry

The injection unit can also be converted at a later date from vertical to horizontal or vice versa.

The machine’s open design makes it particularly well suited for the integration of automation systems with insert feeding and finished parts removal.

At the K 2019, WITTMANN BATTENFELD will demonstrate the functionality of the VPower COMBIMOULD using a VPower 120/130H/210V. With this machine, a plug made of PA and TPE for the automotive industry will be manufactured with a 2+2-cavity mold. The complete automation system for the machine is designed by WITTMANN BATTENFELD Deutschland in Nuremberg. In this application, a Scara robot and a WX142 linear robot from WITTMANN are used, which insert the wrap pins, transfer the preforms, then remove and deposit the finished parts.

The WITTMANN Group

The WITTMANN Group is a worldwide leader in the production of injection molding machines, robots and auxiliaries for the plastics processing industry, headquartered in Vienna/Austria and consisting of two main divisions: WITTMANN BATTENFELD and WITTMANN. They jointly operate the companies of the group with eight production plants in five countries, and its additional sales and service companies are active with 34 facilities on all important plastics markets around the world.

WITTMANN BATTENFELD pursues the further expansion of its market position as an injection molding machine manufacturer and specialist for state-of-the-art process technologies. As a supplier of comprehensive, modern machine technology in modular design, the company meets both present and future market demands for plastics injection molding equipment.

The WITTMANN product portfolio includes robots and automation systems, material handling systems, dryers, gravimetric and volumetric blenders, granulators, temperature controllers and chillers. With this diversified range of peripheral units, WITTMANN offers plastics processors solutions to cover all production requirements, ranging from independent production cells to integrated plant-wide systems.

The syndication of the various segments under the umbrella of the WITTMANN Group has led to complete connectivity between the various product lines, for the benefit of plastics processors with an increasing demand for seamless integration of processing machinery with automation and auxiliaries.

For more informations visit fortuna.gr