A mold change on processing machines is often accompanied by a change of material as well. The latter should proceed as quickly, easily and safely as possible. A single mistake here can lead to serious problems, which in most cases are not detected at once and cause high extra costs in terms of many faulty parts. Using monitored CODEMAX coupling stations from WITTMANN is a way to ensure that the implementation and results of material changes come up to even the most stringent quality standards.

The mechanical design of material distribution systems can vary greatly and may be planned individually. Moreover, these systems can be made from a wide range of different materials, such as entirely from stainless steel, but also from combinations of hardened stainless steel with glass elements – depending on the requirements in each case. WITTMANN deliberately dispenses with welding in producing its material distributors. CODEMAX coupling stations offer a pluggable version with sealed pipe clamps, which permits subsequent exchange of pipe elements and the use of wear-resistant parts where necessary.

The special fast camlock couplings for material transport pipes are manufactured exclusively for use on WITTMANN CODEMAX coupling stations. They consist of aluminum and are fully sealed, are produced without sensitive threading, and are mounted on stainless steel pipes. This is the only way to ensure that any individual requirements specified by customers can actually be met, such as “exclusively stainless steel for parts coming into contact with products”. Their extremely sturdy design also copes with rough handling of the couplings in operation. After all, it quite often happens that material hoses are dropped onto the floor together with the couplings – and must still be able to withstand such incidents without any deformations or other kinds of damage. The camlock couplings ensure safe connections without leakages and can be re-plugged quickly nevertheless.

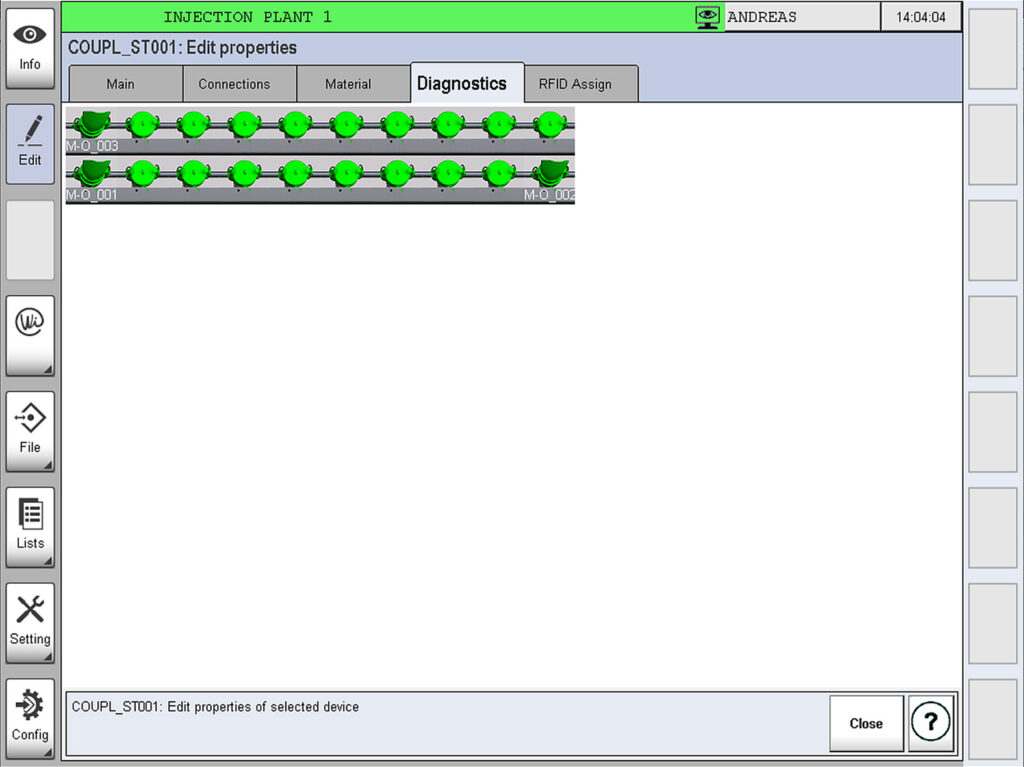

RFID antennas and tags on every coupling make sure that correct connections are established in every case between material feeding pipelines and processing machines. The connections are monitored via the WITTMANN network control for materials handling systems and invariably checked against the input from the system operator. If a coupling process is triggered on the network control system without operator input, this immediately generates an error signal, and the material transport affected is stopped. This reliably prevents feeding of the wrong material to a processing machine. The same procedure is followed if a material change has been triggered via the control system, and the wrong material is connected to the coupling station. Before a coupling process is carried out, the system operator is shown which material hose must be connected to which distributor unit. Both incorrect and open connections are visualized on the control system’s graphic display. All of this ensures in every single case that the processing machines are always supplied with only the required material, and leakages caused by open connections are eliminated as well.

Mounted inside an aluminum housing and over-molded with a shock-absorbing layer of plastic, the RFID antennas are optimally protected against shocks. Existing material distributors can also be retrofitted with RFID antennas, and subsequent extension of monitored coupling stations presents no problems.

There are many good reasons in favor of using a WITTMANN CODEMAX coupling station for distributing materials. CODEMAX is easy to operate, and all currently available coupling options can be retrieved from a central point. With the help of such a system, fast material changes become normal practice, material sources such as dryers, roller containers or external silos can be used by several consumers, and all in all, RFID monitoring ensures a faultless production process.

The WITTMANN Group

The WITTMANN Group is a globally leading manufacturer of injection molding machines, robots and auxiliary equipment for processing a great variety of plasticizable materials – both plastic and non-plastic. The group of companies has its headquarters in Vienna, Austria and consists of two main divisions: WITTMANN BATTENFELD and WITTMANN. Following the principles of environmental protection, conservation of resources and circular economy, the WITTMANN Group engages in state-of-the-art process technology for maximum energy efficiency in injection molding, and in processing standard materials and materials with a high content of recyclates and renewable raw materials. The products of the WITTMANN Group are designed for horizontal and vertical integration into a Smart Factory and can be interlinked to form an intelligent production cell.

The companies of the group jointly operate eight production plants in five countries, and the additional sales companies at their 34 different locations are present in all major industrial markets around the world.

WITTMANN BATTENFELD pursues the continued strengthening of its market position as a manufacturer of injection molding machines and supplier of comprehensive modern machine technology in modular design. The product range of WITTMANN includes robots and automation systems, material handling systems, dryers, gravimetric and volumetric blenders, granulators, temperature controllers and chillers. The combination of the individual areas under the umbrella of the WITTMANN Group enables perfect integration – to the advantage of injection molding processors with an increasing demand for seamless interlocking of processing machines, automation and auxiliaries.

Source: fortuna.gr